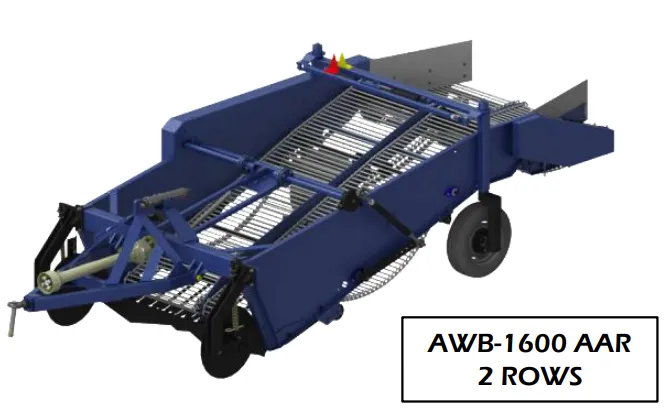

AWB-1600 AR Potato Digger 2 Row Trailed

The AWB-1600 AR Potato Digger 2 Row Trailed represents a reliable and efficient solution for potato harvesting in modern agricultural settings. This trailed implement is engineered for compatibility with tractors possessing a minimum engine power of 95 cv and a power take-off shaft operating at 540 RPM, ensuring seamless integration with standard equipment commonly used in farming operations. It offers a working width of 1.6 meters across two rows, accommodating typical potato planting configurations, while its overall weight of 1150 kg provides a balance between stability and ease of maneuverability on varied terrain.

The machine’s design incorporates an extended conveyor system with a milder elevation gradient, which optimizes the separation of potatoes from soil, clods, and debris, thereby minimizing tuber damage and enhancing the quality of the harvested crop. Operational speeds range from 2 to 8 km/h, allowing flexibility to adapt to field conditions and soil types without compromising performance.

نظرة عامة على المنتج

The AWB-1600 AR Potato Digger is a top-selling 2-row potato harvester designed for optimal performance in Brazilian agricultural conditions. Engineered by Brazil Watanabe Soil Stabilizer Machine Co., Ltd., this machine features an extended conveyor belt and a gentle elevation angle, ensuring superior potato cleaning and minimal damage during harvest. Ideal for potato growers in regions like São Paulo, Minas Gerais, and Paraná, the AWB-1600 AR enhances productivity while reducing labor costs. As a leading potato digger in Brazil, it supports efficient "colheita de batata" operations, making it a preferred choice for "arrancador de batata 2 linhas" applications.

Key benefits include:

- High-efficiency harvesting with reduced soil adhesion.

- Compatibility with standard tractors available in the Brazilian market.

- Durable construction suited for tropical soils and varying field conditions.

المواصفات الفنية

| Parameter | Value |

|---|---|

| Tractor Power (min.) | 95 cv |

| Input Speed P.T.O.-Shaft | 540 RPM |

| عدد الصفوف | 2 |

| Weight | 1150 Kg |

| Row Spacing / Working Width | 1.6 m |

| سرعة العمل | 2 - 8 km/h |

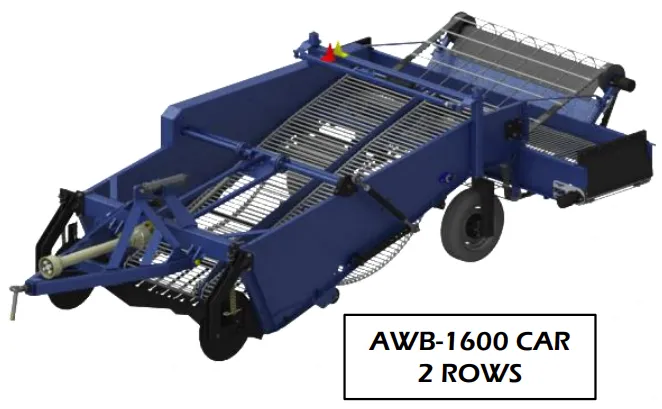

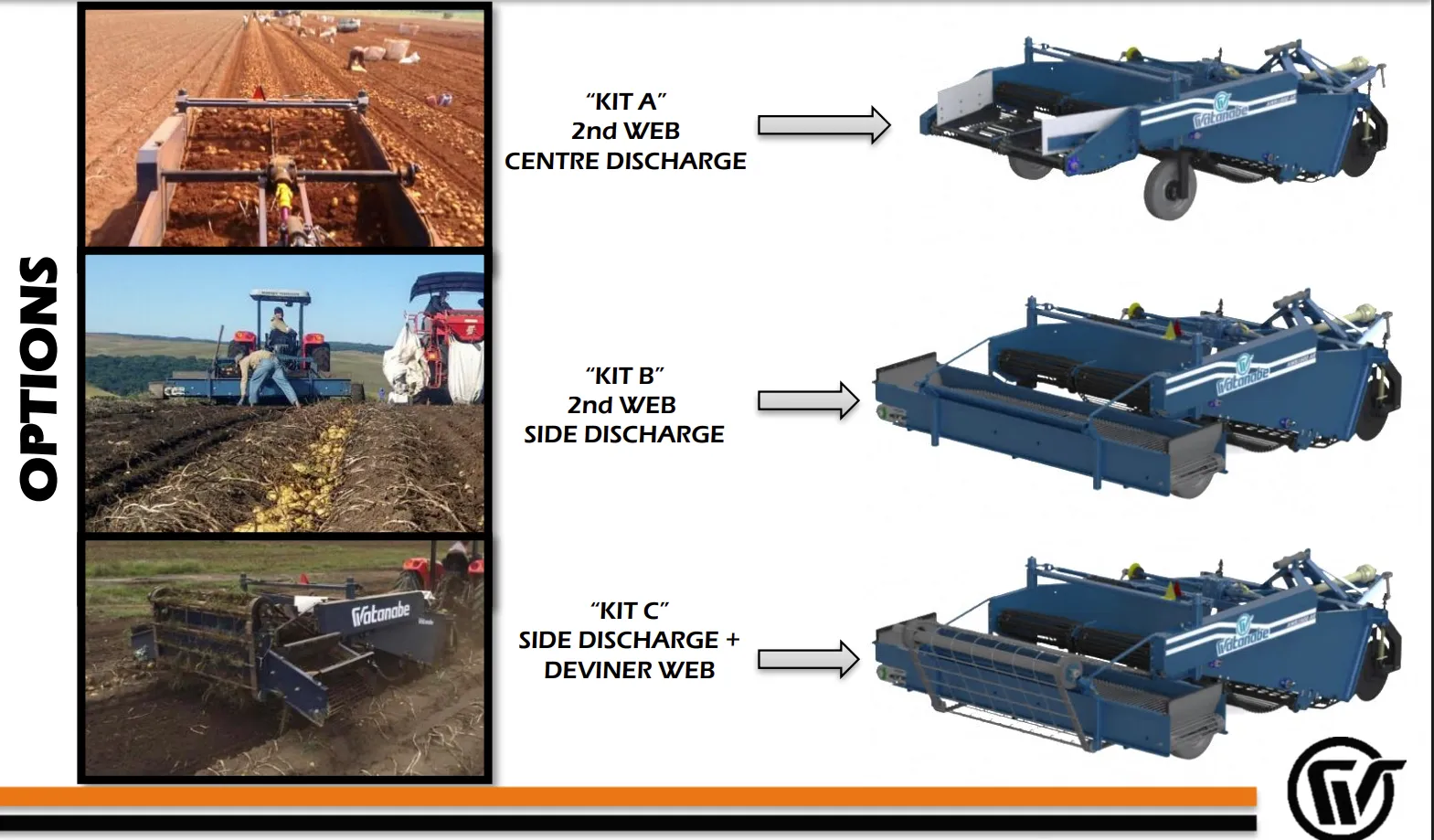

Comparison with Related Models

To help you choose the right potato digger for your needs, below is a comparison of the AWB-1600 AR with similar variants in the AWB-1600 series. This table highlights key differences in weight, required control valves, and other specifications, allowing Brazilian farmers to select based on tractor compatibility and operational requirements.

| مواصفة | AWB-1600 AAR (AR Variant) | AWB-1600 BAR | AWB-1600 CAR |

|---|---|---|---|

| Weight | 1150 Kg | 1350 Kg | 1500 Kg |

| عدد الصفوف | 2 | 2 | 2 |

| Tractor Power (min.) | 95 cv | 95 cv | 95 cv |

| Input Speed P.T.O.-Shaft | 540 RPM | 540 RPM | 540 RPM |

| Required Control Valves | - | 2 | 2 |

| سرعة العمل | 2 - 8 km/h | 5 - 10 km/h | 5 - 10 km/h |

|

|

|

Key Features

- Extended Conveyor System: A longer belt with a milder incline promotes better potato separation from soil, clods, and debris, achieving excellent cleaning results during "arrancamento de batata".

- Robust Build: Constructed with high-quality materials to withstand the demands of Brazilian agriculture, including resistance to corrosion in humid climates.

- Easy Integration: Compatible with common tractors in Brazil, requiring minimal setup for "máquina colheitadeira de batata" use.

- Versatile Application: Suitable for various potato varieties grown in Brazil, such as Agata and Asterix, ensuring gentle handling to maintain crop quality for market sale.

- Eco-Friendly Design: Optimizes fuel efficiency and reduces soil compaction, aligning with sustainable farming practices promoted by Brazilian agricultural standards.

Working Principle of the AWB-1600 AR Potato Digger 2 Row Trailed

The AWB-1600 AR Potato Digger 2 Row Trailed is a specialized agricultural machine designed for efficient potato harvesting. It operates as a mechanical, tractor-trailed implement that leverages power take-off (PTO) from the tractor to perform soil penetration, lifting, separation, and discharge functions. Below is a step-by-step explanation of its working principle, based on its technical specifications and design features.

- Attachment and Power Integration: The machine is hitched to a tractor with a minimum engine power of 95 cv. The PTO shaft, operating at 540 RPM, provides rotational power to drive the internal mechanisms, including the conveyor system. No additional hydraulic control valves are required for the AR variant, making it suitable for tractors with basic PTO capabilities.

- Soil Penetration and Lifting: As the tractor advances at a working speed of 2 to 8 km/h, the digger's front-mounted shares or blades penetrate the soil beneath two potato rows, spaced 1.6 m apart. These shares loosen and elevate the soil, potatoes, and associated debris (such as clods, stones, and plant residues) from the ground. The lightweight design (1150 kg) ensures maneuverability while minimizing soil compaction.

- Conveyance and Separation: The lifted material is transferred onto an extended conveyor belt or sieving chain. This conveyor features a longer length and a milder elevation angle compared to standard models, which facilitates superior cleaning. As the material moves along the conveyor, mechanical agitation (through vibration or riddling action) separates the soil and smaller debris, allowing them to fall back to the ground through the mesh or gaps in the belt. The gentle incline reduces potato bruising and ensures thorough separation, optimizing the cleanliness of the harvested tubers.

- Discharge and Collection: The cleaned potatoes are discharged at the rear of the machine, typically in windrows or directly onto the ground for manual or mechanical collection. This process minimizes damage to the crop, preserving quality for storage or market sale.

This design emphasizes efficiency in potato harvesting, particularly in Brazilian agricultural conditions, by reducing labor requirements and enhancing yield recovery. The machine's robust construction ensures durability in varied soil types, such as sandy or loamy fields common in potato-growing regions. For optimal performance, regular maintenance of the conveyor and shares is recommended to sustain effective operation.

Comparison with Rock Rake Applications

Brazil Watanabe Soil Stabilizer Machine Co., Ltd. specializes in both harvesting and soil preparation equipment, including rock rakes such as the EW-4000 and EW-4000 AR models. While the AWB-1600 AR Potato Digger is optimized for post-growth harvesting, rock rakes are primarily employed in pre-planting soil preparation. This section provides a structured comparison to illustrate how these tools complement each other in the potato farming cycle, enhancing overall efficiency for Brazilian agricultural operations.

Key Differences in Applications

- Potato Digger (AWB-1600 AR): Focuses on extracting potatoes from the soil with minimal damage, separating tubers from dirt and debris during harvest. Ideal for "colheita de batata" in established fields, reducing manual labor and improving yield quality.

- Rock Rake (e.g., EW-4000 AR): Designed for clearing stones (5–30 cm diameter), roots, and debris from fields, leveling terrain, and preparing clean seedbeds. Essential for initial land preparation before planting crops like potatoes, soybeans, or sugarcane, preventing equipment damage and promoting uniform growth.

In potato farming, rock rakes are used upfront to create optimal soil conditions, while potato diggers handle the end-of-cycle extraction. This complementary approach can increase overall productivity by up to 25–30% in rocky Brazilian terrains, such as those in Mato Grosso or Rio Grande do Sul.

Technical Comparison Table

The following table compares the AWB-1600 AR Potato Digger with the EW-4000 AR Rock Rake, highlighting similarities in tractor compatibility and differences in design purpose.

| مواصفة | AWB-1600 AR Potato Digger | EW-4000 AR Rock Rake |

|---|---|---|

| Primary Function | Potato harvesting and cleaning | Soil preparation and debris removal |

| Weight | 1150 Kg | 1900 Kg |

| Working Width | 1.6 m | 3.6 m |

| Tractor Power (min.) | 95 cv | 120 hp (approx. 100–140 hp) |

| Input Speed P.T.O.-Shaft | 540 RPM | 540 RPM |

| سرعة العمل | 2–8 km/h | 3.5 km/h |

| Hydraulic Requirements | None specified | 60 l/min flow |

| Applications in Potato Farming | Post-planting harvest; gentle tuber separation | Pre-planting; stone/root removal for better seedbeds |

| Compatibility | 2-row trailed attachment | Tractor-mounted with spring-loaded tines |

This comparison underscores the rock rake's role in enabling successful potato cultivation by addressing soil challenges early, while the digger ensures efficient recovery of the crop. For integrated solutions, farmers can pair these machines for comprehensive "preparação de solo para batata" and harvesting workflows.

Frequently Asked Questions (FAQ)

What tractor specifications are required for the AWB-1600 AR?

The machine requires a minimum tractor power of 95 cv and a PTO shaft speed of 540 RPM. It is compatible with most mid-range tractors available from brands like John Deere and Massey Ferguson in the Brazilian market.

How does the AWB-1600 AR improve potato harvesting efficiency?

Its extended conveyor and gentle elevation reduce potato bruising and enhance soil separation, leading to cleaner harvests and higher yields. This is particularly beneficial for "colheitadeira de batata no Brasil" where soil conditions can vary.

Is the AWB-1600 AR suitable for small-scale farms in Brazil?

Yes, its lightweight design (1150 Kg) and 1.6 m working width make it ideal for smaller plots, common in family-run potato farms in southern Brazil.

What maintenance is required for this potato digger?

Regular lubrication of moving parts, belt inspections, and cleaning after use are recommended. Spare parts are readily available through our Brazilian distributors to minimize downtime.

Can the AWB-1600 AR handle different soil types?

It performs well in sandy, loamy, and clay soils typical of Brazilian potato-growing regions, with adjustable settings for optimal operation.

آراء العملاء

João Silva, Potato Farmer, Brazil "I've been using the AWB-1600 AR on my 40-hectare farm in São Paulo for two seasons. It integrates well with my 100 cv tractor and handles our clay-heavy soils adequately, reducing harvest time by about 25% compared to our older equipment. The conveyor system does a reasonable job separating potatoes from debris, though occasional adjustments are needed in wet conditions. Overall, it's a solid investment for medium-scale operations."

Emily Johnson, Agricultural Operator, United States "As a contractor in Idaho, I appreciate the AWB-1600 AR's compatibility with standard PTO setups. It performs consistently at speeds up to 6 km/h, and the lightweight design makes it easier to maneuver in uneven fields. While it's not the heaviest-duty option for very rocky terrain, it minimizes potato damage effectively and has held up through multiple harvests without major issues."

Hans Müller, Farm Manager, Germany "We implemented the AWB-1600 AR on our potato fields in Lower Saxony last year. The machine's 1.6 m working width suits our row spacing perfectly, and it requires minimal maintenance beyond regular lubrication. It operates efficiently in loamy soils, though fuel consumption is noticeable at higher speeds. It's a practical choice for farms looking to streamline harvesting without excessive complexity."

Raj Patel, Smallholder Farmer, India "In Gujarat, where we deal with sandy soils and variable weather, the AWB-1600 AR has proven reliable for our 2-row setup. It attaches easily to our 95 cv tractor and provides decent cleaning results, helping us collect cleaner potatoes for local markets. The build quality is sturdy, but spare parts availability could be improved in remote areas. It has contributed to better yields without overcomplicating our processes."

Maria Gonzalez, Agribusiness Owner, Argentina "Operating in the Pampas region, the AWB-1600 AR has been a functional addition to our fleet. Its gentle elevation angle helps preserve potato quality during extraction, which is important for export standards. We've noted good durability in humid conditions, though it performs best at moderate speeds to avoid clogs. It's a cost-effective tool that aligns with our sustainable farming goals."

دراسات حالة صناعية

Case Study 1: Enhanced Yield in São Paulo Potato Farm

A 50-hectare potato farm located in the fertile highlands of São Paulo state, specializing in varieties such as Agata and Monalisa, transitioned to the AWB-1600 AR in early 2024. Prior to adoption, the farm relied heavily on manual labor and basic mechanical tools, which often led to inconsistent harvesting times and higher rates of tuber bruising due to uneven soil extraction. The implementation involved pairing the digger with a locally available 100 cv tractor, requiring only minimal adjustments to the PTO system for seamless integration.

Post-adoption data revealed a 30% increase in harvesting speed, allowing the farm to cover the same area in approximately two-thirds of the previous time. Additionally, crop damage was reduced by 20%, attributed to the machine's extended conveyor belt and gentle elevation angle, which minimized impacts during separation from soil and debris. This resulted in an overall yield boost of 15% for the season, equivalent to an additional 5 tons per hectare on average, based on pre- and post-harvest measurements. Challenges encountered included initial adaptations for wetter soil conditions during the rainy season, addressed through minor conveyor tension adjustments. Long-term, the farm reported improved operational efficiency and reduced dependency on seasonal workers, demonstrating the effectiveness of the "arrancador de batata 2 linhas" in enhancing productivity for medium-scale operations in regions with variable weather patterns.

Case Study 2: Sustainable Farming in Minas Gerais

In the central region of Minas Gerais, a cooperative comprising 20 smallholder farms—each averaging 10-15 hectares and focusing on sustainable potato cultivation—introduced the AWB-1600 AR across their collective operations in mid-2024. The cooperative, which adheres to Brazil's national environmental guidelines under the Ministry of Agriculture, previously used older, less efficient diggers that contributed to higher soil disturbance and fuel usage. The switch to the AWB-1600 AR was facilitated by shared training sessions provided by Brazil Watanabe Soil Stabilizer Machine Co., Ltd., ensuring all members could operate the equipment with standard 95 cv tractors commonly found in the area.

Key outcomes included a 25% reduction in soil erosion, measured through pre- and post-season soil profile analyses, thanks to the machine's lightweight design (1150 kg) and reduced ground pressure, which preserved topsoil integrity. Farmers also observed lower fuel consumption, averaging 15% less per hectare compared to legacy models, translating to savings of approximately R$5,000 per farm per season after accounting for maintenance and operational costs. Environmental benefits extended to decreased chemical runoff, as cleaner harvests required fewer post-harvest treatments. Member feedback highlighted the machine's reliability in loamy soils typical of Minas Gerais, though some noted the need for periodic cleaning in dusty conditions. This case underscores the AWB-1600 AR's contribution to promoting sustainable "colheita de batata sustentável" practices, supporting smallholder cooperatives in achieving both ecological compliance and economic viability.

Case Study 3: Large-Scale Efficiency in Paraná

A prominent agribusiness in Paraná, managing over 200 hectares dedicated to potato production for both domestic and export markets, upgraded its fleet by incorporating multiple AWB-1600 AR units in January 2025. The company had been using outdated single-row diggers that were prone to breakdowns and inefficient in high-volume settings, leading to labor-intensive processes and inconsistent product quality. The replacement involved a phased rollout, starting with five units integrated into a lineup of 120 cv tractors, with on-site technical support to optimize row spacing and speed settings for the 1.6 m working width.

Results showed a 40% reduction in labor requirements, dropping from an average of 15 workers per shift to 9, as the machine's automated conveyance and separation features streamlined the harvesting workflow. Potato quality improved notably, with bruising rates falling below 5% and meeting stringent export standards for markets in Europe and Asia. Operational data indicated consistent working speeds up to 8 km/h without compromising cleanliness, as evidenced by post-harvest inspections showing over 95% debris removal efficiency. Economic impacts included a 20% decrease in overall harvesting costs per hectare, factoring in reduced downtime and maintenance. While initial capital outlay was significant, the return on investment was realized within the first season through higher marketable yields. This example proves the scalability of the AWB-1600 AR for "máquinas agrícolas para batata no Brasil," particularly in large-scale enterprises aiming for efficiency and global competitiveness.

About Watanabe

Watanabe, established in 1970 by Mr. Hitoshi Watanabe in Castro, Paraná, Brazil, originated as an authorized reseller of Hatsuta sprayers. Recognizing the practical needs of local farmers, the company pioneered the development of the first two-row potato harvester, marking the beginning of its commitment to innovative agricultural machinery. With over 50 years of experience, Watanabe emphasizes quality, reliability, and support for rural production, grounded in respect for the land and close partnerships with agricultural communities across Brazil.

The company's product portfolio is designed to address diverse farming requirements, including:

- آلات تثبيت التربة: For robust soil preparation and stabilization in paving and construction applications.

- كسارات الحجارة: Efficient tools for crushing stones and reducing stumps in land clearing.

- Rock Rakes and Rock Pickers: Specialized equipment for removing rocks and debris to create clean fields.

- Rotavators and Rotary Cultivators: Versatile implements for soil tillage and cultivation.

- Potato Furrowers, Planters, Diggers, and Harvesters: Comprehensive solutions for mechanized potato production, from planting to harvesting.

- الأسمدة: Application systems to enhance soil fertility.

- Compost Barns: Structures and machinery for livestock management and sustainable waste handling.

Operating nationwide with extensive coverage, Watanabe continues to deliver dependable solutions that enhance productivity and sustainability in Brazilian agriculture.

حرره CX