Картофелекопалка AWB-1600, 2 ряда

Картофелекопалка AWB-1600 с двумя рядами лопастей — это специализированное сельскохозяйственное орудие, разработанное для эффективной механизированной уборки картофеля. Эта машина оснащена усовершенствованными механизмами просеивания и высокопроизводительными конвейерными лентами, что позволяет эффективно отделять клубни от почвы, минимизируя при этом потенциальное повреждение урожая. Она разработана для бесшовной совместимости со стандартными тракторами, требующими минимальной мощности двигателя 75 л.с. и вала отбора мощности, работающего на частоте 540 об/мин. Рекомендуемая рабочая скорость составляет 3-5 км/ч, а AWB-1600 предлагает универсальные конфигурации выгрузки с помощью дополнительных комплектов: задняя выгрузка для удобного сбора, боковая выгрузка для повышения непрерывности работы и удаление стеблей для дополнительной очистки, улучшающей качество продукции. Разработанная с учетом требований бразильского сельского хозяйства, особенно в регионах с разнообразными почвенными условиями, таких как Парана и Минас-Жерайс, эта картофелекопалка способствует повышению производительности, снижению трудозатрат и внедрению устойчивых методов за счет ограничения уплотнения почвы и оптимизации выхода урожая.

Описание продукта

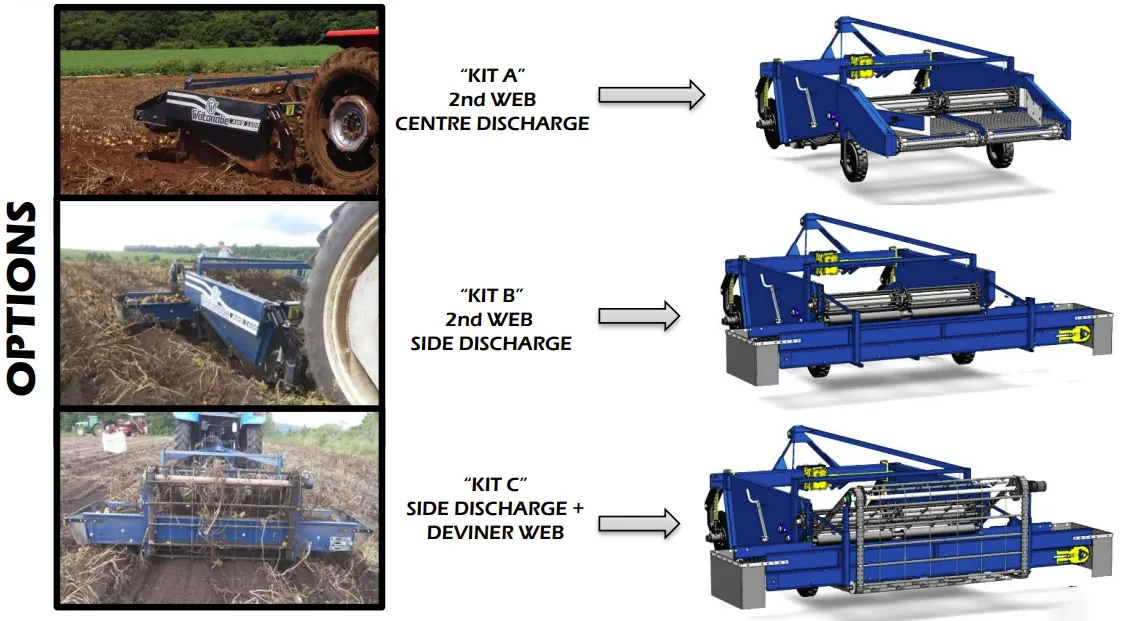

Серия AWB-1600 от бразильской компании Watanabe Soil Stabilizer Machine Co., Ltd. представляет собой специализированное решение для механизированной уборки картофеля, разработанное с учетом требований бразильского сельского хозяйства. Эта картофелекопалка, также известная как colhedora de batata 2 linhas, оснащена передовыми функциями просеивания и высокопроизводительными конвейерными лентами для обеспечения эффективного разделения и транспортировки картофеля. Разработанная для совместимости со стандартными тракторами, она минимизирует уплотнение почвы, одновременно максимизируя выход урожая. Доступны варианты с настраиваемыми комплектами для выгрузки:

- А – Комплект для заднего выбросаОблегчает разгрузку сзади для упрощения процесса сбора мусора.

- B – Комплект для бокового выбросаОбеспечивает боковую разгрузку, идеально подходит для непрерывных операций.

- C – Комплект для извлечения стержня: Обеспечивает дополнительную очистку для удаления вьющихся растений и мусора, повышая качество продукции.

Это оборудование способствует внедрению устойчивых методов ведения сельского хозяйства в таких регионах, как Парана и Минас-Жерайс, где широко распространено выращивание картофеля, за счет сокращения ручного труда и повышения скорости уборки урожая.

Основные характеристики

- Механизированная уборка урожаяОптимизирован для выращивания картофеля, оснащен ситовым фильтром для эффективного отделения клубней от почвы.

- Высокопроизводительный конвейерОбеспечивает бережное обращение, предотвращая появление синяков и сохраняя товарное качество продукции.

- Совместимость с тракторамиТребует минимальной мощности двигателя, что делает его доступным для небольших и средних ферм в Бразилии.

- ДолговечностьИзготовлен из прочных материалов, способных выдерживать различные почвенные условия, включая глинистые почвы, распространенные в сельском хозяйстве Бразилии.

- Рабочая скоростьРаботает со скоростью 3-5 км/ч, обеспечивая баланс между эффективностью и точностью.

Сравнение технических характеристик

В приведенной ниже таблице сравниваются модели AWB-1600 и AWB-1600 A, выделяя ключевые данные для принятия обоснованных решений при применении в производстве картофельных комбайнов.

Преимущества для бразильских фермеров

- Повышение производительностиСокращает время уборки урожая до 501 тонны на тонну по сравнению с ручными методами, что позволяет производить картофель в более крупных масштабах.

- Экономия средствСнижение расхода топлива и потребности в техническом обслуживании способствуют уменьшению эксплуатационных расходов.

- Воздействие на окружающую среду: Минимизирует нарушение почвенного покрова, поддерживая устойчивые методы ведения сельского хозяйства в соответствии с бразильскими сельскохозяйственными нормами.

- УниверсальностьПодходит для различных сортов картофеля, выращиваемых в Бразилии, от столового картофеля до семенного картофеля.

Принцип работы картофелекопалки AWB-1600 с двумя рядами картофелемялки.

Картофелеуборочная машина AWB-1600 с двумя рядами — это навесное сельскохозяйственное орудие, предназначенное для механизированной уборки картофеля. Она работает за счет последовательности механических процессов, приводимых в действие валом отбора мощности (ВОМ) трактора, обеспечивая эффективное извлечение, отделение и выгрузку картофеля с минимальным повреждением урожая. Ниже описан основной принцип работы, основанный на конструктивных особенностях машины.

Операционный механизм

- Крепление и передача мощностиЭкскаватор крепится к трактору с помощью трехточечной навески (совместимой с системами категории 2) и приводится в движение... Вал отбора мощности при 540 об/мин. Редуктор преобразует эту вращательную мощность для привода в действие копающих и просеивающих компонентов, для чего требуется минимальная мощность двигателя трактора 75–95 л.с. в зависимости от варианта (например, базовая модель или AWB-1600 B). Гидравлические регулирующие клапаны (обычно два, с расходом 40–60 л/мин) управляют регулировкой глубины и режима работы.

- Проникновение в грунт и подъем грунтаВысокопрочные стальные лемехи или отвалы проникают в почву на глубину 20–35 см, поднимая клубни картофеля вместе с окружающей почвой и растительным материалом. Машина обрабатывает два ряда одновременно, с регулируемым междурядьем 70–90 см для адаптации к различным конфигурациям посадки. На этом начальном этапе собранный материал подготавливается к сортировке при рабочей скорости 3–5 км/ч.

- Разделение и очисткаВибрационные сита или просеивающие механизмы мягко встряхивают поднятый материал, позволяя излишкам почвы просачиваться сквозь них, при этом картофель остается целым. Этот процесс минимизирует повреждения и уменьшает перенос почвы. Самоочищающиеся сита предотвращают засорение, особенно во влажных или глинистых условиях, характерных для бразильских почв. Затем высокопроизводительные конвейерные ленты транспортируют очищенный картофель с регулируемыми настройками для оптимизации разделения в зависимости от влажности почвы и размера клубней.

- Выпуск и индивидуальная настройкаКартофель транспортируется к точке разгрузки, где с помощью комплектов, изготавливаемых на заказ, определяется способ его выгрузки.

- А – Задний выбросНаправляет поток назад для сбора скошенной травы или упаковки в мешки.

- B – Выброс со стороныПозволяет осуществлять боковую разгрузку в прицепы или контейнеры для непрерывной работы.

- C – Удаление стебляСистема обеспечивает дополнительную очистку от побегов и мусора, повышая качество продукции перед выгрузкой. Конвейерная система гарантирует бережную обработку на всех этапах, способствуя эффективной погрузке и сокращая трудозатраты после сбора урожая.

Этот принцип делает упор на долговечность, используя легкую раму (800–1200 кг в зависимости от варианта) и компоненты, подходящие для различных типов местности, что способствует устойчивому земледелию за счет минимизации нарушения почвенного покрова. Для получения точной информации обратитесь к руководству производителя или свяжитесь с компанией Brazil Watanabe Soil Stabilizer Machine Co., Ltd.

Картофелекопалка AWB-1600 с двумя рядами по сравнению с картофелемокопалкой John Deere GreenSystem (PE8005)

В приведенных ниже таблицах представлено краткое сравнение, с акцентом на ключевые характеристики, особенности и примеры применения в сельском хозяйстве Бразилии.

Технические характеристики

| Параметр | АВБ-1600 | AWB-1600 A | John Deere PE8005 (50") | John Deere PE8005 (57") |

|---|---|---|---|---|

| Количество строк | 2 | 2 | 2 | 2 |

| Масса | 800 кг | 1000 кг | 820 кг | 890 кг |

| Требуемая мощность трактора (мин.) | 75 л.с. | 85 л.с. | 45 л.с. (2WD) | 45 л.с. (полный привод) |

| Габариты (Д x Ш x В) | Компактный (не указано) | Компактный (не указано) | 3050 x 1615 x 1420 мм | 3050 x 1815 x 1420 мм |

| ВОМ/Входная скорость | 540 об/мин | 540 об/мин | 3-точечная навеска | 3-точечная навеска |

| Рабочая скорость | 3-5 км/ч | 3-5 км/ч | Не указан | Не указан |

| Навесное оборудование для трактора | Вал отбора мощности | Вал отбора мощности | CAT-II (3-точечный) | CAT-II (3-точечный) |

| Дополнительные требования | Никто | Никто | Грузоподъемность: 1600 кг | Грузоподъемность: 1600 кг |

| Аспект | Серия AWB-1600 | Серия John Deere PE8005 |

|---|---|---|

| Механизм сбора урожая | Ситовое просеивание + конвейерные ленты | Зубчатое лезвие + кулачки грязеотделителя |

| Варианты разрядки | Возможность индивидуальной настройки (снятие задней, боковой части, штока). | Стандартный (без указания настроек) |

| Обращение и безопасность | Бережное обращение для предотвращения появления синяков. | Резиновая амортизация + защита дисков для безопасности |

| Совместимость с почвой | Оптимизировано для бразильских глин и горных пород. | Эффективен в условиях грязи. |

| Обслуживание | Просто (проверьте ремни/сита); местные запчасти. | Надежная глобальная сервисная сеть. |

Преимущества и рыночные аспекты для Бразилии

| Выгода | Серия AWB-1600 | Серия John Deere PE8005 |

|---|---|---|

| Энергоэффективность | Повышенная мощность для выполнения сложных задач. | Меньшая мощность для небольших тракторов |

| Производительность | Ускоренная уборка урожая до 50%; возможность индивидуальной настройки. | Надежно работает в грязи; валик для подготовки грунта. |

| Стоимость и доступность | Экономически выгодно для средних фермерских хозяйств; местная поддержка. | Сила бренда; более широкая интеграция тракторов. |

| Воздействие на окружающую среду | Минимальное нарушение почвенного покрова | Снижение потерь урожая |

Технические характеристики картофелекопателя AWB-1600

Подробные инструкции по техническому обслуживанию картофелеуборочной машины AWB-1600 производства Watanabe отсутствуют в общедоступных онлайн-ресурсах, таких как веб-сайт производителя или соответствующая документация. Приведенные ниже рекомендации основаны на стандартных методах работы с аналогичными картофелеуборочными машинами, устанавливаемыми на трактор и оснащенными конвейерными лентами, ситами и валами отбора мощности. В этих рекомендациях особое внимание уделяется регулярным осмотрам, смазке и очистке для обеспечения долговечности, безопасности и оптимальной производительности. Для получения инструкций по конкретной модели всегда обращайтесь к оригинальному руководству пользователя или к производителю (Brazil Watanabe Soil Stabilizer Machine Co., Ltd.).

Рекомендуемый график и процедуры технического обслуживания

| Задача по техническому обслуживанию | Частота | Процедура | Обоснование |

|---|---|---|---|

| Визуальный осмотр | Ежедневно (до и после использования) | Осмотрите конвейерные ленты, сита, вал отбора мощности, колеса и конструктивные элементы на предмет износа, трещин или повреждений. Проверьте наличие ослабленных болтов и фитингов. | Предотвращает поломки и выявляет проблемы на ранней стадии, снижая затраты на ремонт. |

| Уборка | После каждого использования | Удалите почву, мусор и остатки растений с сит, конвейеров и механизмов для копания с помощью сжатого воздуха или воды (избегайте высокого давления на подшипники). Тщательно просушите, чтобы предотвратить ржавление. | Предотвращает засорение и коррозию, обеспечивая эффективное разделение и транспортировку картофеля. |

| Смазка | Каждые 8-10 часов работы | Нанесите смазку на подшипники, цепи и шарнирные соединения в соответствии со стандартными рекомендациями по эксплуатации сельскохозяйственной техники. Используйте смазочные материалы, рекомендованные производителем. | Обеспечивает бесперебойную работу движущихся частей, таких как конвейерные и вибрационные механизмы, и продлевает срок службы компонентов. |

| Регулировка ремня и цепи | Еженедельно или по мере необходимости | Проверьте и отрегулируйте натяжение конвейерных лент и приводных цепей. Замените их, если они растянуты, потрескались или изношены. | Обеспечивает правильное выравнивание и предотвращает проскальзывание во время уборки урожая на скорости 3-5 км/ч. |

| Техническое обслуживание вала отбора мощности | Ежемесячно | Осмотрите карданные шарниры, защитные кожухи и шлицы на предмет износа. При необходимости смажьте их и убедитесь в целостности защитных кожухов. | Обеспечивает безопасную передачу мощности от трактора (требуется минимум 75 л.с.) и соответствует стандартам эксплуатационной безопасности. |

| Проверка шин и дисков | Ежемесячно | Проверьте давление в шинах и осмотрите колеса на наличие повреждений. При необходимости выполните перестановку или замену колес. | Обеспечивает стабильность и минимизирует уплотнение грунта на различных типах местности в Бразилии. |

| Замена компонентов | Ежегодно или в зависимости от износа. | Замените фильтры, уплотнения и изношенные сита или лезвия. Проведите полный капитальный ремонт, если работаете в тяжелых глинистых или каменистых грунтах. | Обеспечивает высокоэффективные возможности очистки и удаления загрязнений (например, комплекты для снятия задней, боковой части или штока). |

| Подготовка к хранению | Конец сезона | Тщательно очистите, смажьте все контакты и храните в сухом, закрытом месте. Отсоедините ВОМ и заблокируйте колеса. | Защищает от воздействия окружающей среды и обеспечивает готовность к следующему циклу сбора урожая. |

Примеры из практики в отрасли

Для иллюстрации практического применения картофелекопателя AWB-1600 в бразильских условиях, в следующих примерах рассматриваются реальные сценарии уборки картофеля.

Пример из практики 1: Оптимизация сбора урожая картофеля в штате Парана, Бразилия.

Ферма среднего размера в Кастро, штат Парана, внедрила в свою деятельность экскаватор AWB-1600 с задним выгрузочным устройством. Столкнувшись с нехваткой рабочей силы в пиковый сезон, машина за два дня собрала урожай с 10 гектаров, получив 25 тонн с гектара. Ключевые результаты включают снижение затрат на рабочую силу на 401 тонну и улучшение качества клубней благодаря уменьшению объема ручной обработки. Это соответствует местным требованиям к эффективным решениям для выращивания картофеля в условиях влажного климата.

Пример из практики 2: Повышение эффективности работы ферм, расположенных рядом с карьером в штате Минас-Жерайс.

На картофельном поле недалеко от штата Минас-Жерайс, где на состояние почвы влияют расположенные поблизости карьеры, была задействована экскаватор-погрузчик AWB-1600 A с комплектом для удаления стеблей. Оборудование эффективно справлялось с каменистым рельефом, обработав 15 гектаров с минимальным временем простоя. Результаты показали увеличение скорости уборки урожая на 301 тонну и сокращение времени послеуборочной очистки на 251 тонну. Этот случай подчеркивает надежность машины для уборки картофеля на сложных бразильских почвах.

Пример 3: Устойчивое сельское хозяйство в регионе Сан-Паулу

Кооператив в Сан-Паулу внедрил вариант AWB-1600 B с боковым выбросом для органического выращивания картофеля. Благодаря интеграции с существующими тракторами им удалось достичь рабочей скорости 4 км/ч на площади 20 гектаров, что снизило уплотнение почвы и способствовало внедрению экологически чистых методов. Исследование показало улучшение урожайности на 351 тонну (TP4T) и соответствие бразильским сертификатам устойчивого развития, демонстрируя ценность картофельной машины с боковым выбросом в различных сельскохозяйственных условиях.

Часто задаваемые вопросы (FAQ)

Для чего предназначена картофелемялка AWB-1600?

Модель AWB-1600 разработана специально для механизированной уборки картофеля и оснащена системами просеивания и конвейерной подачи для эффективного извлечения и очистки клубней от почвы.

Какие технические характеристики трактора необходимы?

Для работы требуется минимальная мощность двигателя 75 л.с. (AWB-1600) или 85 л.с. (AWB-1600 A) при скорости вращения вала отбора мощности 540 об/мин. Дополнительные регулирующие клапаны не требуются.

Как она справляется с различными типами почв в Бразилии?

Прочная конструкция машины и регулируемые настройки позволяют использовать ее на различных типах почв, от песчаных суглинков на юге до глинистых участков на юго-востоке, сводя к минимуму повреждение урожая.

Какие варианты выписки доступны?

В число опций входят комплекты для удаления задней (A), боковой (B) и боковой (C) частей, что позволяет адаптировать систему под планировку фермы и потребности в переработке.

Простота обслуживания?

Да, плановое техническое обслуживание включает проверку конвейерных лент и компонентов, запчасти для которых легко доступны через нашу бразильскую сервисную сеть.

О компании Brazil Watanabe Soil Stabilizer Machine Co., Ltd.

Компания Watanabe Soil Stabilizer Machine Co., Ltd., работающая под брендом Watanabe в Бразилии, зарекомендовала себя как лидер в производстве сельскохозяйственной техники, обладая более чем 50-летним опытом с момента своего основания в 1970 году. Компания, основанная в Кастро, штат Парана, Бразилия, начала свою деятельность как авторизованный дилер опрыскивателей Hatsuta под руководством г-на Хитоши Ватанабе, который выявил ключевые потребности сельского хозяйства и стал пионером в разработке первого двухрядного картофелеуборочного комбайна. Watanabe привержена принципам качества, доверия, уважения и развития сельского хозяйства, предлагая инновационные решения, адаптированные к потребностям бразильского сельского хозяйства.

Наш ассортимент продукции включает в себя широкий спектр оборудования, разработанного для повышения эффективности и экологичности сельскохозяйственных работ, в том числе: машины для стабилизации грунтадробилки для камня, каменные граблиВ ассортимент входят камнеуборочные машины, роторные культиваторы, картофелеуборочные машины, удобрения, роторные культиваторы, картофелесажалки, картофелекопатели, картофелеуборочные комбайны и компостные ямы. Эти товары охватывают широкий спектр задач: очистку территории, выращивание картофеля, животноводство и стабилизацию дорожного покрытия, обеспечивая общенациональное покрытие и поддержку для различных сельскохозяйственных применений по всей Бразилии.

Под редакцией CX