CBW-2L Potato Harvester – 2 Rows

The CBW-2L Potato Harvester represents a reliable and efficient solution for two-row potato harvesting, developed by Brazil Watanabe Soil Stabilizer Machine Co., Ltd to meet the demands of modern agricultural operations. This tractor-mounted machine measures 8,800 mm in length, 3,200 mm in width, and 3,900 mm in height, with an empty weight of 4,500 kg, ensuring stability and durability across varied field conditions. It is equipped to support big bags with a capacity of up to 700 kg each, facilitating seamless collection and transport during harvest activities.

To operate effectively, the CBW-2L requires a tractor with a minimum engine power of 100 cv, a cardan shaft input at 540 RPM, and two control valves for hydraulic integration. Its working speed ranges from 2 to 5 km/h, allowing operators to adjust based on soil type, crop density, and terrain to optimize performance while minimizing tuber damage. The design emphasizes high yield through gentle handling, featuring a multi-stage conveyor system with webs for soil separation, vine removal, and quality inspection.

Přehled produktu

The CBW-2L Potato Harvester is a high-performance, 2-row machine designed specifically for efficient potato harvesting in demanding agricultural environments. Engineered by Brazil Watanabe Soil Stabilizer Machine Co., Ltd, this harvester combines robust construction with user-friendly features to maximize yield and minimize downtime. Ideal for Brazilian potato farmers seeking reliable equipment, the CBW-2L supports big bags up to 700 kg and operates at speeds of 2 to 5 km/h, ensuring smooth handling and easy maintenance.

For optimal performance in Brazil's diverse soil conditions, this machine is tailored to enhance productivity in potato cultivation regions such as Minas Gerais, São Paulo, and Paraná. Key SEO terms for Brazilian market: colheitadeira de batata 2 linhas, máquina colhedora de batata Brasil, colheitadeira de alto rendimento para batata.

CBW-2L Potato Harvester Image Note: The image depicts the CBW-2L model with its blue canopy, conveyor system, and tractor hitch.

Technické specifikace

The following table outlines the key technical data for the CBW-2L, providing a clear overview of its dimensions, weight, and operational requirements.

| Kategorie | Specifikace |

|---|---|

| Dimensions | |

| Length (mm) | 8800 |

| Width (mm) | 3200 |

| Height (mm) | 3900 |

| Weight | |

| Prázdná hmotnost | 4500 Kg |

| Tractor Requirements | |

| Cardan Shaft Input Revolutions | 540 RPM |

| Engine Power (min.) | 100 koní |

| Control Valves Required | 2 |

| Performance | |

| Pracovní rychlost | 2 - 5 Km/h |

| Big Bag Support | Up to 700 Kg |

Features and Benefits

- High Yield Design: Developed for maximum efficiency, the CBW-2L ensures gentle potato handling to reduce bruising and maintain crop quality, crucial for Brazilian export markets.

- Easy Maintenance: Features accessible components and a straightforward design, allowing quick servicing in the field to minimize operational interruptions.

- Smooth Operation: Equipped with a reliable conveyor system and adjustable settings, it adapts to various soil types common in Brazilian agriculture.

- Compatibility: Requires a standard tractor with at least 100 cv power, making it suitable for mid-sized farms across Brazil.

- Trvanlivost: Built with high-quality materials to withstand the rigors of intensive use in tropical climates.

Comparison Table: CBW-2L vs. Standard Industry Models

To highlight the advantages of the CBW-2L, the table below compares it with typical 2-row potato harvesters available in the Brazilian market. Data is based on general industry standards; actual competitor specs may vary.

| Funkce | CBW-2L | Standard Competitor A | Standard Competitor B |

|---|---|---|---|

| Length (mm) | 8800 | 8500 | 9000 |

| Width (mm) | 3200 | 3000 | 3400 |

| Height (mm) | 3900 | 3800 | 4000 |

| Empty Weight (Kg) | 4500 | 4200 | 4800 |

| Min. Engine Power (cv) | 100 | 120 | 90 |

| Working Speed (Km/h) | 2-5 | 1-4 | 3-6 |

| Big Bag Capacity (Kg) | 700 | 500 | 600 |

| Maintenance Ease | High (User-Friendly) | Medium | Low |

| Yield Efficiency | High | Medium | High |

This comparison demonstrates the CBW-2L's balanced design, offering superior big bag support and easier maintenance while maintaining competitive dimensions and power requirements.

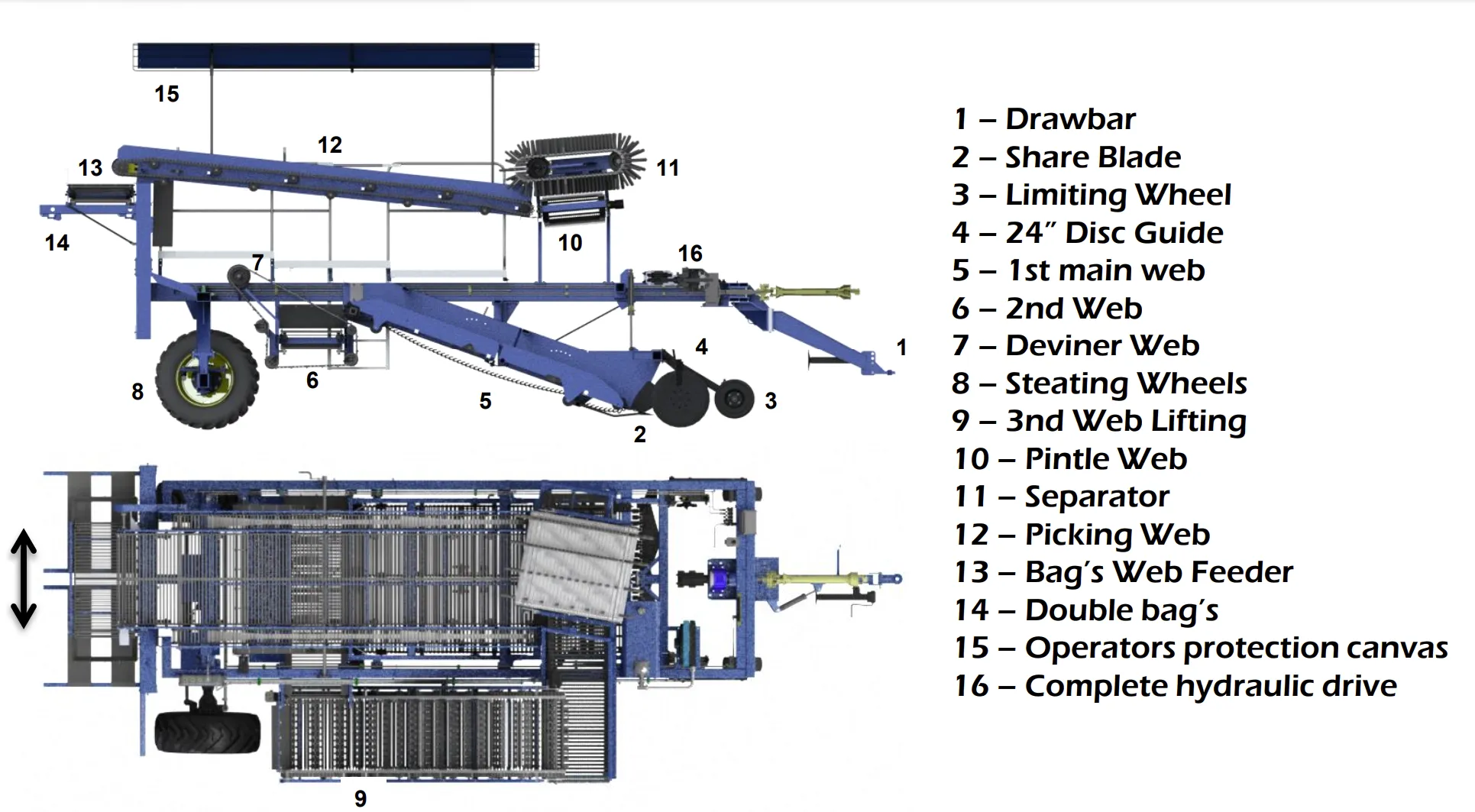

Components of CBW-2L Potato Harvester

The CBW-2L Potato Harvester is a specialized agricultural machine designed for efficient potato extraction, separation, and collection. Below is a detailed explanation of each labeled component based on standard potato harvester engineering principles. These components work in sequence to dig, separate, clean, and prepare potatoes for bagging while minimizing crop damage and soil contamination.

- Drawbar This is the structural hitch or towing bar that connects the harvester to the tractor. It transmits pulling force from the tractor to the machine, ensuring stable alignment during operation and allowing for easy attachment and detachment.

- Share Blade The share blade, also known as the digging share or ploughshare, is the primary cutting tool that penetrates the soil to lift potato tubers from the ground. It is designed to slice through the earth with minimal resistance, uprooting the crop while avoiding excessive soil disturbance.

- Limiting Wheel These wheels regulate the depth of the share blade's penetration into the soil. By limiting how deeply the machine digs, they prevent over-excavation, protect the potatoes from bruising, and ensure consistent harvesting depth across varying field conditions.

- 24" Disc Guide The 24-inch disc guides are rotating discs that flank the digging area. They cut and guide the soil and plant material into the harvester's intake, helping to define the row boundaries, reduce side spillage, and assist in initial separation of vines or debris.

- 1st Main Web The first main web is a conveyor sieve or chain belt that receives the uprooted potatoes and soil from the share blade. It vibrates or moves to shake off initial layers of dirt, allowing smaller soil particles to fall through while advancing the potatoes to subsequent stages.

- 2nd Web This secondary conveyor web continues the separation process from the first web. It provides additional sieving to remove more adhered soil, clods, or small debris, enhancing cleaning efficiency in multi-stage designs, particularly in clay-heavy soils.

- Deviner Web The deviner web is specialized for removing potato vines (haulms) and foliage. It uses agitation or separation mechanisms to detach and eject plant tops, preventing them from mixing with the harvested tubers and reducing contamination in the final output.

- Steating Wheels Likely referring to steering or supporting wheels (possibly a variant of "steering wheels"), these provide directional control and stability to the harvester. They allow for precise maneuvering in the field, support the machine's weight, and help maintain alignment with crop rows during turns or uneven terrain.

- 3rd Web Lifting This mechanism enables the lifting or adjustment of the third web conveyor. It facilitates maintenance, cleaning, or height adjustments to optimize separation based on soil type or crop conditions, ensuring the web can be raised for transport or lowered for operation.

- Pintle Web The pintle web is a type of chain-driven conveyor, often featuring pintle (pin-like) linkages for durability. It transports potatoes through intermediate stages, providing robust movement while allowing further soil separation, and is commonly used in harvesters for its strength in handling heavy loads.

- Separator The separator distinguishes potatoes from remaining soil clods, stones, or other non-crop material. It employs vibration, air flow, or mechanical sorting to isolate clean tubers, improving overall harvest quality and reducing the need for manual post-harvest cleaning.

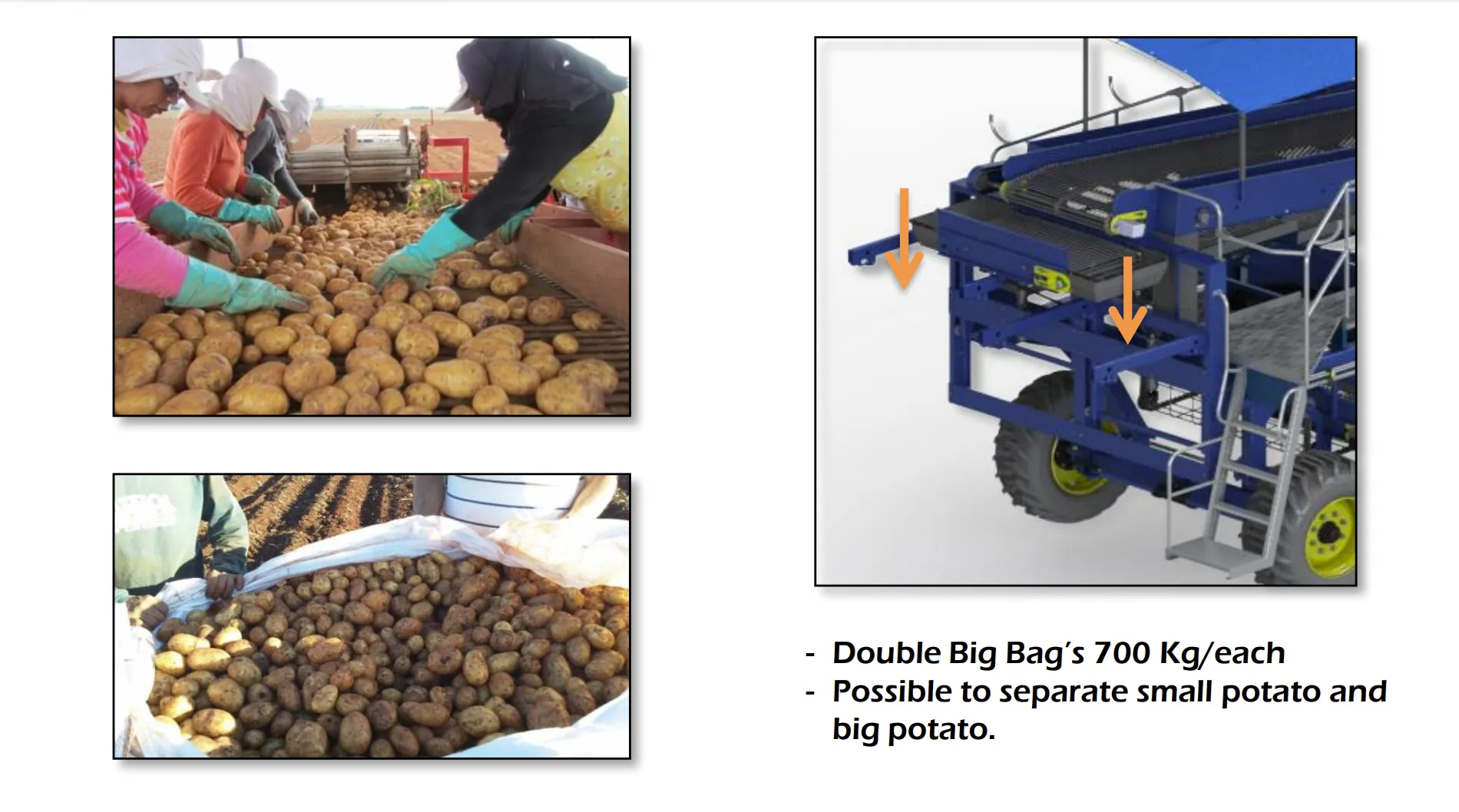

- Picking Web This is an inspection conveyor where operators can manually pick out defective potatoes, stones, or debris. It moves the crop slowly for visual assessment, ensuring only high-quality produce proceeds to collection, which is essential for market-grade standards.

- Bag's Web Feeder The bag's web feeder is a conveyor extension that directs cleaned potatoes into bagging systems. It feeds the tubers gently into bags or containers, controlling flow to prevent overflow or damage, and integrates with the harvester's output for efficient packaging.

- Double Bag's This refers to a dual-bag support system, allowing simultaneous filling of two bags (up to 700 kg each, as per model specifications). It enhances productivity by enabling continuous operation without frequent stops, ideal for high-yield harvesting scenarios.

- Operators Protection Canvas The operators' protection canvas is a canopy or protective cover that shields machine operators from environmental elements such as sun, rain, dust, or falling debris. It promotes safety and comfort during extended field operations.

- Complete Hydraulic Drive This encompasses the full hydraulic system that powers various moving parts, including conveyors, lifts, and adjustments. It provides precise control, efficient energy transfer from the tractor's PTO, and reliable operation under demanding conditions, reducing mechanical wear.

Recenze zákazníků

João Silva, Farmer from Brazil (Minas Gerais)

We have been using the CBW-2L for two seasons on our 200-hectare potato farm. It handles the clay soils here adequately, with the multi-web system effectively separating tubers from debris. Maintenance is straightforward, as components are accessible, though we needed occasional adjustments to the hydraulic drive in wet conditions. Overall, it has improved our harvest efficiency without major issues.

Maria Gonzalez, Agricultural Operator from Argentina

In our operations in the Pampas region, the CBW-2L has proven reliable for 2-row harvesting. The big bag support up to 700 kg streamlines collection, reducing the need for additional labor. We appreciate the depth control via limiting wheels, which minimizes crop damage. However, in very sandy soils, some soil clods pass through the separators, requiring minor manual sorting. It fits well with our mid-sized tractors.

Thomas Leclerc, Farm Manager from France

Deployed on our potato fields in Normandy, the machine's 2-5 km/h working speed aligns with our need for careful handling to maintain tuber quality for market. The complete hydraulic drive ensures consistent operation, and the deviner web efficiently removes foliage. Durability is solid, though replacement parts for the webs took a few weeks to arrive. It offers good value for medium-scale farms.

Raj Patel, Grower from India (Punjab Region)

We adapted the CBW-2L for our potato cultivation in irrigated fields. The share blade digs effectively at required depths, and the picking web allows for quality checks during harvest. It requires a 100 cv tractor, which matches our equipment. In humid conditions, we noted some rust on exposed metal after extended use, but regular maintenance mitigates this. Productivity has increased modestly.

Emily Carter, Farm Owner from the United States (Idaho)

On our Idaho potato ranch, the CBW-2L integrates smoothly with our operations. The 24" disc guides help in row alignment, and the separator reduces post-harvest cleaning time. It's user-friendly for operators, with the protection canvas providing necessary shelter. We experienced no major breakdowns in the first year, though fuel efficiency could be better at higher speeds. A practical choice for consistent yields.

Často kladené otázky

What tractor specifications are required to operate the CBW-2L?

The CBW-2L requires a tractor with a minimum engine power of 100 cv, a cardan shaft operating at 540 RPM, and two control valves. This setup ensures compatibility with standard mid-sized agricultural tractors commonly used in potato farming operations.

How does the CBW-2L perform in different soil types?

The machine is designed for versatility across various soil conditions, including clay, sandy, and loamy soils. Its adjustable limiting wheels and multi-web separation system help maintain effective digging and cleaning, though performance may vary in extremely wet or rocky terrains, where minor adjustments could be necessary.

What is the expected lifespan and maintenance schedule for the CBW-2L?

With regular maintenance, the CBW-2L can operate reliably for 5-10 years, depending on usage intensity. Routine checks include lubricating moving parts, inspecting webs for wear, and cleaning after each use. Annual professional servicing is recommended to ensure optimal functionality.

Can the CBW-2L be adapted for harvesting other crops, such as onions?

While primarily optimized for potatoes, the CBW-2L shares similarities with onion harvesters in its conveyor and separation mechanisms. Minor modifications, such as adjusting the share blade depth, may allow use with similar root crops, but dedicated testing is advised for best results.

What warranty and support options are available?

The CBW-2L comes with a standard one-year warranty covering manufacturing defects. Extended warranty plans are available upon request. Our global support network provides parts replacement and technical assistance, with response times typically within 48 hours for inquiries.

How does the big bag support system function, and what is its capacity?

The system supports big bags up to 700 kg each, with a double bag configuration for continuous operation. Potatoes are fed directly via the bag's web feeder, allowing efficient collection without interrupting the harvesting process.

What are the key differences between the CBW-2L and competing potato harvesters?

Compared to standard models, the CBW-2L offers balanced dimensions, easier maintenance, and superior big bag capacity. It requires slightly higher tractor power but provides enhanced yield efficiency through its multi-stage web system, as detailed in our comparison tables.

About Brazil Watanabe Soil Stabilizer Machine Co., Ltd

Brazil Watanabe Soil Stabilizer Machine Co., Ltd, established in 1970 by Sr. Hitoshi Watanabe in Castro, Paraná, Brazil, originated as an authorized reseller of Hatsuta sprayers. The company evolved to address local agricultural needs, notably developing the first two-row potato harvester in response to farmer requirements. With more than 50 years of experience, the organization emphasizes respect for the environment, dedication to rural development, and the provision of reliable agricultural solutions.

The company's product portfolio encompasses a range of specialized machinery designed to support efficient farming practices, including soil stabilizer machines, stone crushers, hrábě na kameny, rock pickers, rotavators, potato furrowers, fertilizers, rotary cultivators, potato planters, potato diggers, potato harvesters, and compost barns. These offerings are categorized into key lines such as pavement and soil stabilization, livestock management, potato cultivation, and area clearing equipment, ensuring comprehensive coverage for diverse operational demands across Brazil.

Committed to quality and customer proximity, Brazil Watanabe Soil Stabilizer Machine Co., Ltd maintains a nationwide presence to facilitate timely support and product accessibility.

Upraveno uživatelem CX