CT-2100 Rock Pickers Stone Collector

The CT-2100 Rock Pickers Stone Collector, manufactured by Brazil Watanabe Soil Stabilizer Machine Co., Ltd., represents a specialized auxiliary apparatus engineered for the precise and efficient extraction of stones, roots, and miscellaneous debris from irregular landscapes within agricultural and construction contexts. This machine integrates a sophisticated rotary mechanism that facilitates the collection and propulsion of materials weighing up to 80 kilograms, thereby enabling comprehensive terrain clearance without excessive soil disruption. Complementing this is a hydraulically actuated tilting bucket with a substantial capacity of 2.5 cubic meters, designed to expedite unloading processes and minimize operational interruptions.

Compatibility is assured with tractors possessing a minimum power output of 120 horsepower, operating across a working width of 1.95 meters at controlled velocities ranging from 3 to 5 kilometers per hour, while requiring a hydraulic flow rate of at least 60 liters per minute. Such specifications ensure seamless integration into existing workflows, enhancing overall productivity by automating labor-intensive tasks and safeguarding subsequent equipment from potential damage caused by subsurface obstacles. Particularly suited for the diverse and often challenging terrains encountered in Brazilian regions, the CT-2100 contributes to improved soil quality, reduced maintenance expenditures, and accelerated project timelines in sectors such as field preparation, site leveling, and land reclamation.

Descripción general del producto

The CT-2100 Rock Pickers Stone Collector is a specialized auxiliary equipment designed for efficient cleaning of irregular terrain in agricultural and construction applications. Engineered by Brazil Watanabe Soil Stabilizer Machine Co., Ltd., this robust machine integrates seamlessly with soil stabilization systems, facilitating the removal of stones, roots, and debris to prepare surfaces for optimal productivity.

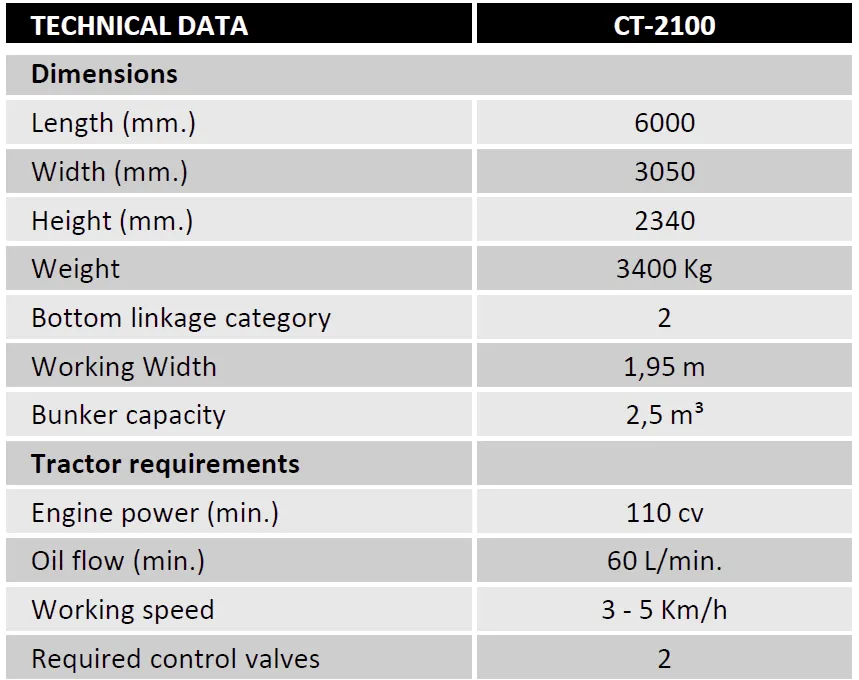

Technical Specifications Table

| Parameter | Especificación |

|---|---|

| Compatible Tractor | 120 hp |

| Working Width | 1.95 m |

| Bucket Capacity | 2.5 m³ |

| Minimum Hydraulic Flow | 60 l/min |

| Velocidad de trabajo | 3 to 5 km/h |

| Throwing Capacity | Stones and debris up to 80 kg |

| Bucket System | Tilting for easy unloading |

Key Features

- Rotary System: Enables the collection and throwing of stones and debris weighing up to 80 kg, ensuring thorough clearance of challenging areas.

- Tilting Bucket Mechanism: Features a 2.5 m³ capacity bucket with a hydraulic tilting system for quick and effortless unloading, minimizing operational downtime.

- Compatibility and Performance: Compatible with tractors of at least 120 hp, operating at a working width of 1.95 m and speeds ranging from 3 to 5 km/h, with a minimum hydraulic flow requirement of 60 l/min.

Benefits

This equipment enhances soil preparation efficiency by automating the removal process, reducing manual labor, and preventing equipment damage from obstacles. It is particularly suited for rocky or uneven soils prevalent in Brazilian regions, promoting higher agricultural yields and streamlined construction workflows.

Comparison Table

| Aspect | CT-2100 Rock Pickers | Standard Rock Rake (Competitor) | Manual Method |

|---|---|---|---|

| Working Width | 1.95 m | 1.5 m | Variable (labor-limited) |

| Bucket Capacity | 2.5 m³ | 1.8 m³ | N/A (requires separate vehicles) |

| Velocidad de trabajo | 3-5 km/h | 2-4 km/h | 1-2 km/h |

| Throwing Capacity | Up to 80 kg | Up to 50 kg | Up to 20 kg per worker |

| Efficiency in Irregular Areas | High (rotary system) | Medium | Low (high injury risk) |

| Minimum Hydraulic Flow | 60 l/min | 70 l/min | N/A |

| Primary Application | Brazilian agriculture and construction | General cleaning | Small areas |

Working Principle of the CT-2100 Rock Pickers Stone Collector

The CT-2100 Rock Pickers operates as an auxiliary agricultural and construction machine designed to clear irregular terrain by systematically collecting and removing stones, roots, and debris. Its core mechanism relies on hydraulic power integration with a compatible tractor, enabling efficient soil preparation while minimizing manual intervention. The system functions through a combination of mechanical rotation for collection and hydraulic actuation for unloading, ensuring precise control and high productivity in challenging environments.

Operational Mechanism

The machine attaches to a tractor rated at a minimum of 120 horsepower, utilizing the tractor's hydraulic system with a flow rate of at least 60 liters per minute. As the tractor moves forward at a controlled speed of 3 to 5 kilometers per hour, the CT-2100 engages its primary components across a working width of 1.95 meters. The process begins with ground engagement, where debris is directed into the collection area.

- Rotary System Functionality: At the heart of the CT-2100 is a hydraulically driven rotary mechanism, typically consisting of a drum or rake assembly equipped with durable tines or blades. This system rotates to agitate and lift stones and debris from the soil surface. The centrifugal force generated by the rotation propels collected materials—up to 80 kilograms in weight—into the integrated bucket. This design prevents clogging and allows for continuous operation on uneven ground, separating larger obstacles from finer soil particles.

The rotary action is calibrated to maintain efficiency without excessive soil disturbance, promoting sustainable land management.

- Tilting Bucket Mechanism: Once collected, materials accumulate in a 2.5 cubic meter capacity bucket. The bucket employs a hydraulic tilting system, activated via the tractor's controls, to facilitate unloading. This mechanism pivots the bucket at an optimal angle, allowing gravity-assisted discharge of contents at designated sites. The tilting ensures rapid emptying, reducing cycle times and enhancing overall workflow.

Safety features, such as controlled hydraulic valves, prevent accidental tipping during transit.

Integration and Efficiency Considerations

The CT-2100's principle emphasizes modularity, allowing seamless integration with soil stabilization equipment. Hydraulic power ensures responsive operation, while the machine's robust construction withstands demanding conditions typical in Brazilian agricultural regions. By automating debris removal, it mitigates risks associated with manual methods, such as equipment damage or operator fatigue, thereby optimizing resource utilization.

Application Scenarios for the CT-2100 Rock Pickers Stone Collector

The CT-2100 Rock Pickers Stone Collector, developed by Brazil Watanabe Soil Stabilizer Machine Co., Ltd., serves as a specialized auxiliary machine for removing stones, roots, and debris from irregular terrain. Its design, incorporating a rotary system and tilting bucket, renders it suitable for demanding environments where efficient land preparation is essential. This equipment finds primary utility in agriculture and construction sectors, where it enhances productivity by automating debris clearance, thereby reducing manual labor and mitigating potential damage to subsequent machinery.

Agricultural Field Preparation

In agricultural settings, the CT-2100 is employed to clear fields of rocks and roots prior to planting or tillage operations. This process prevents damage to plows, planters, and harvesters while improving soil quality and promoting uniform crop growth. For instance, on Brazilian soybean or corn farms in regions such as Paraná or Mato Grosso, the machine operates at speeds of 3 to 5 km/h to systematically collect debris up to 80 kg, facilitating rapid reclamation of rocky soils. Such applications have been shown to boost farm efficiency and protect soil integrity through advanced rock-picking technologies. Additionally, it integrates with soil stabilization equipment to prepare land for high-yield cultivation, reducing downtime and labor costs significantly.

Construction Site Land Clearing

Within construction projects, the CT-2100 facilitates site preparation by removing obstacles from uneven ground, ensuring a stable foundation for infrastructure development. It is particularly effective in rural road building or building site leveling in areas like Minas Gerais, where rocky terrain predominates. The machine's 1.95 m working width and 2.5 m³ bucket capacity enable efficient debris handling in harsh conditions common to both agricultural and construction markets. This application minimizes manual intervention, accelerates project timelines, and supports hydraulic operations compatible with 120 hp tractors, making it ideal for large-scale land clearing tasks.

Pasture and Land Reclamation

For pasture management and land reclamation efforts, the CT-2100 aids in restoring degraded areas by extracting embedded stones and roots, thereby enhancing drainage and vegetation establishment. In Brazilian livestock operations or environmental restoration initiatives, it promotes sustainable land use by preparing surfaces for reseeding or erosion control measures. The equipment's ability to handle diverse debris types underpins its role in reducing long-term maintenance needs and improving overall land productivity.

Opiniones de clientes

We value feedback from our users worldwide. Below are selected reviews from customers in various countries, highlighting their experiences with the product in different applications.

João Silva, Farmer, Brazil "I have been using the CT-2100 on my soybean fields in Paraná for over a year. It handles rocky soil effectively, collecting stones up to 80 kg without much issue. The tilting bucket makes unloading straightforward, though it requires regular hydraulic checks in humid conditions. Overall, it has reduced my preparation time compared to manual methods."

Emily Carter, Construction Supervisor, United States "As part of our site preparation team in Texas, the CT-2100 integrates well with our 120 hp tractors. Its 1.95 m working width covers ground efficiently at 3-5 km/h speeds. We've noticed improved durability in rough terrain, but the minimum hydraulic flow of 60 l/min means we had to adjust some older equipment. It's a practical addition for debris removal."

Michael Thompson, Ranch Owner, Australia "On my cattle property in Queensland, the CT-2100 helps clear roots and debris from pastures. The 2.5 m³ bucket capacity allows for fewer trips to unload, which is helpful in large areas. It performs reliably in dry, uneven land, though dust buildup requires occasional cleaning. It has made land maintenance more manageable without excessive downtime."

Sophie Laurent, Land Reclamation Specialist, Canada "We deployed the CT-2100 for restoring logged areas in British Columbia. The rotary system picks up debris consistently, aiding in soil stabilization efforts. Compatibility with our tractors is solid, and the operational speed fits our workflow. Maintenance is straightforward, but we recommend monitoring the rotary components for wear in forested environments."

Frequently Asked Questions (FAQ)

What is the primary function of the CT-2100 Rock Pickers?

The CT-2100 serves as an auxiliary machine for collecting and removing stones, roots, and debris from irregular terrain. It employs a rotary system to gather materials up to 80 kg and a tilting bucket for unloading, making it suitable for soil preparation in agriculture and construction.

How does the CT-2100 Rock Pickers operate?

It attaches to a compatible tractor and uses hydraulic power to drive a rotary mechanism that lifts and propels debris into a 2.5 m³ bucket. Operating at speeds of 3 to 5 km/h across a 1.95 m working width, it requires a minimum hydraulic flow of 60 l/min. The tilting system then allows for controlled unloading at designated sites.

What tractor specifications are required for compatibility?

The machine is compatible with tractors rated at a minimum of 120 horsepower. It integrates via the tractor's hydraulic system, necessitating at least 60 l/min flow. Users should verify their equipment meets these standards to ensure proper performance.

In what types of terrain does the CT-2100 perform best?

It is effective on relatively flat to moderately uneven surfaces, such as rocky fields or construction sites. Performance may vary in extremely wet or heavily forested areas, where additional preparation could be needed to avoid soil disturbance or component wear.

How does the CT-2100 compare to traditional rock removal methods?

Unlike manual picking or basic rakes, the CT-2100 automates the process with hydraulic efficiency, reducing labor requirements and time. It minimizes soil disruption compared to some traditional approaches, though it may not handle very large boulders beyond 80 kg.

What maintenance is recommended for the CT-2100?

Regular inspections of hydraulic components every 200 hours of use are advised, along with cleaning the rotary system to prevent buildup from dust or debris. Periodic checks on the tilting mechanism and lubrication of moving parts help maintain longevity, particularly in humid or dusty environments.

Is the CT-2100 a worthwhile investment for my operation?

This depends on the scale and frequency of rock removal needs. For farms or sites with persistent debris issues, it can reduce downtime and equipment damage, potentially offering a return on investment through improved efficiency. Smaller operations might evaluate based on specific terrain challenges.

Can the CT-2100 be used in conjunction with other equipment?

Yes, it integrates well with soil stabilizers or other attachments from Brazil Watanabe Soil Stabilizer Machine Co., Ltd. This allows for comprehensive land preparation workflows, such as combining debris removal with soil treatment.

Acerca de Brasil Watanabe Soil Stabilizer Machine Co., Ltd.

Established in 1970 by Sr. Hitoshi Watanabe in Castro, Paraná, Brazil, our company originated as an authorized distributor of Hatsuta sprayers. Recognizing the practical requirements of local farmers, we pioneered the development of the first two-row potato harvester, initiating a legacy spanning over five decades dedicated to advancing rural production, fostering respect for agricultural communities, and promoting responsible land management.

We specialize in delivering high-quality agricultural machinery renowned for reliability and performance. Our product lines encompass:

- Area Cleaning Solutions: Equipment for land preparation, including stone collection, crushing, stump removal, and waste processing.

- Potato Harvesting Systems: Advanced machinery designed for efficient mechanized potato operations.

- Livestock Management Tools: Innovations such as Compost Barn systems and straw shredders.

- Paving and Soil Stabilization Equipment: Robust systems for soil enhancement and infrastructure development.

With extensive operations throughout Brazil, we prioritize quality assurance, building enduring trust, and forming collaborative partnerships with farmers and industry stakeholders to support sustainable agricultural practices. For further details, please visit our website or contact our team.