Σταθεροποιητής εδάφους / Μηχανές κοπής εδαφών / Λιθοθρυμματιστές

Βραζιλία Watanabe Soil Stabilizer Machine Co.,Ltd

Το Watanabe είναι ποιότητα και εμπιστοσύνη

Με πάνω από 55 χρόνια ακλόνητης συνεργασίας με τους αγρότες, η Watanabe αποτελεί ακρογωνιαίο λίθο της γεωργικής καινοτομίας από την ίδρυσή της το 1970 στο Κάστρο της Παρανά της Βραζιλίας. Ξεκινώντας ως εξουσιοδοτημένος αντιπρόσωπος των ψεκαστικών Ichida, ο ιδρυτής μας, κ. Watanabe Jin, δημιούργησε βαθιές σχέσεις με τους τοπικούς αγρότες για να κατανοήσει πραγματικά τις προκλήσεις τους, οδηγώντας στην ανάπτυξη του πρωτοποριακού μας μηχανήματος συγκομιδής πατάτας δύο σειρών. Η ραγδαία επιτυχία του μηχανήματος και η αυξανόμενη ζήτηση της αγοράς ώθησαν την ίδρυση ενός ειδικού εργοστασίου μηχανημάτων πατάτας το 1976. Μετά τον θάνατο του κ. Watanabe το 1983, η κληρονομιά του συνεχίστηκε με αγάπη από τη σύζυγο και τα παιδιά του, τα οποία μετονόμασαν την εταιρεία το 1984 σε Watanabe Máquinas Agrícolas Indústria e Comércio Ltda. Σήμερα, συνεχίζουμε να καλλιεργούμε την αριστεία στην καλλιέργεια πατάτας, επεκτείνοντας παράλληλα την εξειδίκευσή μας σε λύσεις βαμβακιού, ζαχαροκάλαμου, δασοκομίας, σταθεροποίησης εδάφους, χειρισμού υλικών και αποθήκευσης, παρέχοντας στιβαρά, επικεντρωμένα στους αγρότες μηχανήματα που ενισχύουν την παραγωγικότητα και τη βιωσιμότητα σε όλη τη Βραζιλία και πέρα από αυτήν. Ως υπερήφανη θυγατρική αυτής της ιστορικής επιχείρησης, η Brazil Watanabe Soil Stabilizer Machine Co., Ltd. ειδικεύεται σε προηγμένες τεχνολογίες σταθεροποίησης εδάφους και θραύσης πετρωμάτων, βασιζόμενη στην κληρονομιά της μητρικής μας εταιρείας για να παρέχει εξατομικευμένες λύσεις υψηλής απόδοσης για τις σύγχρονες ανάγκες κατασκευών και διαχείρισης γης.

Βρείτε μας

Οπου

Rodovia Pr 151, 281,6 | Distrito Industrial | Κάστρο – PR | Βραζιλία

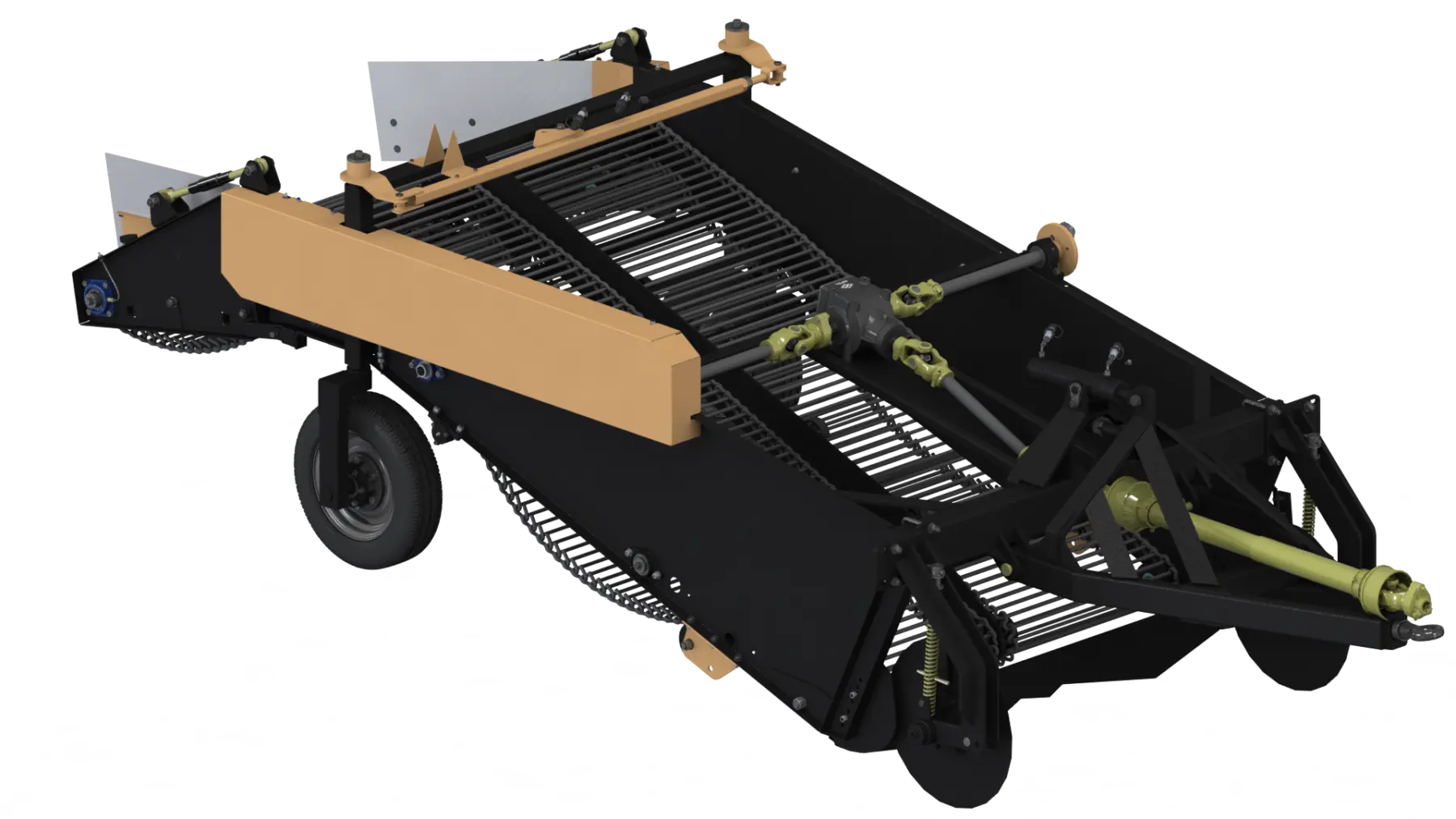

Τα προϊόντα μας

ΚΑΘΑΡΙΣΜΟΣ ΧΩΡΟΥ

ΠΑΤΑΤΕΣ

ΖΩΑ

ΛΙΘΟΣΤΡΩΣΗ

Αυλακωτής πατάτας

Περιστροφικός καλλιεργητής

Γλάστρα πατάτας

Πατατοσκαφείς

Συγκομιδή Πατάτας

Αχυρώνας κομποστοποίησης

Σχετικά με την Βραζιλία Γουατανάμπε

Από το 1970, η Watanabe ενσαρκώνει την ακλόνητη ποιότητα και διασφάλιση, που βασίζονται στον βαθύ σεβασμό για τη γη και στο πάθος για την προώθηση της αγροτικής παραγωγής μέσω καινοτόμων λύσεων σταθεροποίησης του εδάφους.

Κριτικές πελατών

«Έχω χρησιμοποιήσει το Watanabe Soil Stabilizer Machine σε πολλά έργα αποκατάστασης δρόμων σε περιόδους βροχών. Χειρίζεται την ανάμειξη υπολειμμάτων ασφάλτου στη βάση χωρίς πολύ σκάλισμα και η απόδοση είναι σταθερή περίπου στα 7-8 μίλια/ώρα σε επίπεδο έδαφος. Δεν είναι το ταχύτερο που υπάρχει, αλλά κάνει τη δουλειά του αξιόπιστα όταν το έδαφος είναι μαλακό. Είδαμε λιγότερη διάβρωση στις πλαγιές μετά την επεξεργασία, κάτι που μας γλίτωσε από την επανεπεξεργασία. Η συντήρηση είναι απλή, αν και τα υνιά χρειάζονται ακόνισμα μετά από 200 ώρες.»

-Τζον Ραμίρεζ, Εργολάβος Κατασκευών, Ηνωμένες Πολιτείες (Τέξας)

«Η ομάδα μας λειτουργεί καθημερινά τον θραυστήρα βράχου Watanabe σε λατομεία ασβεστόλιθου. Οι σιαγόνες αντέχουν καλά σε βράχους 5-7 εκατοστών, συνθλίβοντας περίπου 50-60 τόνους ανά βάρδια χωρίς σοβαρές βλάβες. Χρειάστηκε να συγκολλήσουμε εξαρτήματα που φθείρονται μερικές φορές μετά από έξι μήνες, κάτι που αναμένεται σε συνθήκες τριβής. Είναι ανθεκτικό για την τιμή του, αλλά συμβαίνουν μπλοκαρίσματα εάν το υπερφορτώσετε — χρειάζονται περίπου 30 λεπτά για να καθαριστεί. Συνολικά, μας βοήθησε να μειώσουμε το κόστος μεταφοράς μας από το εργοτάξιο.»

-Priya Singh, Χειρίστρια Μεταλλείων, Ινδία (Ρατζαστάν)

«Ως χειριστής μικρής κλίμακας, ο θραυστήρας πέτρας Watanabe που είναι συνδεδεμένος στο τρακτέρ μας ήταν πρακτικός για τον καθαρισμό πετρών από χωράφια. Η εγκατάσταση είναι απλή με το κιτ ρυμούλκησης και επεξεργάζεται υλικό πάχους 2,5-4 εκατοστών σε λεπτότερη βάση χωρίς ιδιαίτερη ταλαιπωρία. Το λειτουργούμε σε χαμηλότερες ταχύτητες για να αποφύγουμε το φράξιμο και είναι διαχειρίσιμο για ένα άτομο. Δεν είναι ιδανικό για πολύ υγρό έδαφος, καθώς μπορεί να βουλώσει, αλλά για ξηρά χωράφια, είναι αρκετά αποτελεσματικό για να προετοιμάσει το έδαφος για φύτευση.»

-Λίαμ Τόμσον, Αγρότης, Αυστραλία (Νέα Νότια Ουαλία)

«Χρησιμοποιήσαμε τον Σταθεροποιητή Εδάφους Watanabe σε ένα έργο σταθεροποίησης αυτοκινητοδρόμων. Συμπυκνώνεται καλά με ελάχιστα χημικά πρόσθετα, διατηρώντας την αντοχή του καθ' όλη τη διάρκεια του χειμώνα χωρίς ιδιαίτερη υποβάθμιση. Το αρχικό κόστος ήταν λογικό σε σύγκριση με την ενοικίαση μεγαλύτερων μονάδων και εξοικονομήσαμε υπερβολική εκσκαφή με την επεξεργασία επί τόπου. Η κατανάλωση καυσίμου είναι περίπου 20-25 λίτρα ανά ώρα, κάτι που αθροίζεται, αλλά ο μειωμένος χρόνος διακοπής λειτουργίας το καθιστά άξιο λόγου. Η υποστήριξη από την Watanabe ήταν άμεση όταν χρειαστήκαμε ανταλλακτικά.»

-Άννα Μύλερ, Μηχανικός Υποδομών, Γερμανία (Βαυαρία)

«Η ασφάλεια είναι το κλειδί στα έργα μας σε πλαγιές λόφων, και ο θραυστήρας βράχου Watanabe διαθέτει σταθερούς προφυλακτήρες που αποτρέπουν τις εκτοξεύσεις κατά τη λειτουργία. Συνθλίβει τα τσιμεντένια υπολείμματα από παλιές εγκαταστάσεις σε επαναχρησιμοποιήσιμα υλικά, βοηθώντας στην οικολογική απόρριψη. Επεξεργαζόμαστε περίπου 40 τόνους ημερησίως, αλλά ο θόρυβος και η σκόνη απαιτούν μάσκες και ωτοασπίδες. Δεν είναι αθόρυβο ή χωρίς σκόνη, αλλά καλύτερο από το χειροκίνητο σπάσιμο. Δεν υπάρχουν σοβαρά περιστατικά σε ένα χρόνο, αν και ελέγχουμε τακτικά τους ιμάντες για να αποφύγουμε τα γλιστρήματα.»

-Carlos Oliveira, Ειδικός σε Αναδασμούς Γης, Βραζιλία (Minas Gerais)

«Αφού αγοράσαμε τον θραυστήρα πέτρας Watanabe, αντιμετωπίσαμε ένα πρόβλημα με την ευθυγράμμιση του ρότορα στην αρχή. Η ομάδα σέρβις τους ανταποκρίθηκε εντός μιας εβδομάδας και το επισκεύασε εντός εγγύησης—χωρίς επιπλέον κόστος. Τώρα λειτουργεί ομαλά σε γρανίτη, αποδίδοντας 1 ίντσα μείον με αξιοπρεπή ρυθμό. Τα διαστήματα συντήρησης είναι κάθε 100 ώρες, κάτι που ταιριάζει στο πρόγραμμά μας. Δεν είναι χωρίς συντήρηση, αλλά τα ανταλλακτικά είναι οικονομικά προσιτά και διαθέσιμα τοπικά.»

-Thabo Nkosi, Διευθυντής Λατομείου, Νότια Αφρική (Γκαουτένγκ)

«Σε συνθήκες παγετού, το Watanabe Soil Stabilizer αντέχει με τα σφραγισμένα εξαρτήματά του, αποτρέποντας το πάγωμα. Το χρησιμοποιούμε για την προετοιμασία της βάσης σε χωματόδρομους, αναμειγνύοντας αδρανή υλικά χωρίς να συσσωρεύονται. Η ταχύτητα μειώνεται στα 8 χλμ/ώρα στο χιόνι, αλλά σταθεροποιείται αποτελεσματικά για την κυκλοφορία. Έχουμε παρατηρήσει καλύτερη μακροζωία από τα παλαιότερα μοντέλα που είχαμε, αν και η θέρμανση του υδραυλικού συστήματος βοηθά σε θερμοκρασίες υπό το μηδέν.»

-Έλενα Πέτροβα, Κατασκευαστής Οδοποιίας, Ρωσία (Σιβηρία)

«Ο θραυστήρας βράχου Watanabe προσαρμόζεται καλά σε ψαμμίτες και ανακυκλωμένο σκυρόδεμα στα αστικά μας έργα. Αλλάζει εύκολα τις ρυθμίσεις των σιαγόνων για διαφορετικά μεγέθη, παράγοντας εύχρηστο γέμισμα για θεμέλια. Η ευελιξία είναι ένα πλεονέκτημα, αλλά σε υψηλές θερμοκρασίες, παρακολουθούμε την υπερθέρμανση—προσθέτουμε ένα σύντομο διάλειμμα κάθε λίγες ώρες. Είναι λειτουργικός για μικτές εργασίες χωρίς να χρειάζονται πολλαπλά μηχανήματα.»

-Μοχάμεντ Άλι, Εργολάβος, Ηνωμένα Αραβικά Εμιράτα (Ντουμπάι)

«Το μηχάνημα σταθεροποίησης εδάφους Watanabe αποτελεί μέρος των προσπαθειών μας για τον έλεγχο της παράκτιας διάβρωσης. Αναμιγνύει το έδαφος ομοιόμορφα με ταχύτητα περίπου 6-7 χλμ./ώρα, χρησιμοποιώντας περίπου 18 λίτρα καυσίμου ανά ώρα σε μέτριο έδαφος. Έχουμε παρατηρήσει εξοικονόμηση στο κόστος προσθέτων, καθώς συμπιέζεται καλά χωρίς επιπλέον υλικά, αλλά σε αμμώδεις περιοχές, απαιτεί περισσότερα περάσματα για να επιτευχθεί σταθερότητα. Συνολικά, είναι λειτουργικό, αν και παρακολουθούμε στενά τα καύσιμα για να διαχειριζόμαστε τους προϋπολογισμούς.»

-Σοφι Λοράν, Πολιτικός Μηχανικός, Γαλλία (Νορμανδία)

Μελέτες Περιπτώσεων Έργου

Αποκατάσταση Οδών σε Υγρό Έδαφος Τέξας (Ηνωμένες Πολιτείες)

Υπό την καθοδήγηση της τεχνικής ομάδας του Watanabe κατά τη διάρκεια μιας πιλοτικής δοκιμής το 2023, το έργο αυτό σταθεροποίησε 15 μίλια αγροτικών δρόμων που ήταν επιρρεπείς σε πλημμύρες. Το μέλος της ομάδας, μηχανικός Alex Kim, διεξήγαγε επιτόπιες δοκιμές: Η ανάλυση εδάφους πριν από το έργο έδειξε περιεκτικότητα σε άργιλο 25%, οδηγώντας σε ένα προσαρμοσμένο πρωτόκολλο ανάμειξης. Διαδικασία λειτουργίας: (1) Προετοιμασία χώρου - καθαρισμός υπολειμμάτων και ισοπέδωση της επιφάνειας. (2) Σύνδεση σταθεροποιητή σε τρακτέρ 150HP. (3) Ρύθμιση βάθους ρότορα σε 10 ίντσες, προσθήκη νερού για υγρασία 18%. (4) Ανάμειξη σε περάσματα 6-8 mph, συμπύκνωση με ρολό. (5) Σκλήρυνση για 48 ώρες. Δεδομένα: Επιτεύχθηκε παραγωγή 300 τόνων/ημέρα. Η αντοχή σε ανεμπόδιστη συμπίεση αυξήθηκε από 50 psi σε 150 psi μετά την επεξεργασία. Προκλήσεις: Η πλακόστρωση που προκλήθηκε από τη βροχή καθυστέρησε τις εργασίες κατά το 20%, αντιμετωπίστηκε μέσω σταδιακής ξήρανσης. Αποτελέσματα: Η διάβρωση μειώθηκε κατά 50%, σύμφωνα με τις επόμενες έρευνες. Το έργο ολοκληρώθηκε εντός προϋπολογισμού, εξοικονομώντας 15% σε υλικά.

Επέκταση λατομείου ασβεστόλιθου στο Ρατζαστάν (Ινδία)

Σε μια αναβάθμιση λατομείου το 2024, η ομάδα του Watanabe συνεργάστηκε με χειριστές για την ανάπτυξη του θραυστήρα βράχου. Ο τεχνικός Raj Patel επέβλεψε την εγκατάσταση και τις δοκιμές: Προσομοιωμένα φορτία επιβεβαίωσαν χωρητικότητα 60 τόνων/ώρα σε ασβεστόλιθο 3 ιντσών. Διαδικασία: (1) Ανατίναξη και φόρτωση πετρωμάτων μέσω εκσκαφέα. (2) Τροφοδοσία στον θραυστήρα με σιαγόνες με ελεγχόμενο ρυθμό. (3) Πρωτογενής σύνθλιψη σε 4 ίντσες, δευτερογενής σε 1 ίντσα μέσω κώνου. (4) Κόσκινο και αποθήκευση. (5) Καθημερινοί έλεγχοι για φθορά. Δεδομένα: Επεξεργασία 1.500 τόνων/βάρδια σε διάστημα 8 μηνών. απόδοση καυσίμου 22 λίτρα/ώρα. Προκλήσεις: Η λειαντική σκόνη προκάλεσε χρόνο διακοπής λειτουργίας για τον καθαρισμό των φίλτρων. Μετριάστηκε με καταστολή του νερού. Αποτελέσματα: Το κόστος μεταφοράς μειώθηκε κατά 30%, επιτρέποντας την επέκταση του χώρου χωρίς εξωτερικούς προμηθευτές.

Σταθεροποίηση βάσης οδικού δικτύου Permafrost στη Δυτική Σιβηρία (Ρωσία)

Το 2024, ένα έργο οδοποιίας πετρελαιοπηγών μήκους 20 χλμ. στο μόνιμα παγωμένο έδαφος του Τιουμέν (βάθος έως 1300 μ.) χρησιμοποίησε το Soil Stabilizer. Η ειδικός Έλενα Πέτροβα δοκίμασε μείγματα με τύρφη και άργιλο υψηλής υγρασίας, χρησιμοποιώντας τσιμέντο 10-20%. Διαδικασία: (1) Προετοιμασία για το χειμώνα για την κατεψυγμένη βάση. (2) Σύνδεση σε τρακτέρ. (3) Ανάμειξη στα 6-8 mph με γεωσυνθετικά. (4) Συμπύκνωση με μόνωση. (5) Παρακολούθηση 6 μηνών. Δεδομένα: 250 τόνοι/ημέρα, αντοχή στα 11-21 MPa. Προκλήσεις: Καθυστερήσεις από ρωγμές στους -50°C, μειωμένες με συγκρατητήρες. Αποτελέσματα: Σταθερότητα 1,5-2x, μείωση κόστους 1,5-1,9x.

Εκχέρσωση γεωργικής γης στη Νέα Νότια Ουαλία (Αυστραλία)

Ένα μικρό αγροκτηματικό έργο δοκίμασε τον Stone Crusher το 2022, με επικεφαλής τις δοκιμές πεδίου, την γεωπόνο της ομάδας Lisa Wong. Οι δοκιμές εδάφους αποκάλυψαν βραχώδεις μάντρες με περιεκτικότητα σε πέτρα 20%. Διαδικασία: (1) Σύνδεση με τρακτέρ 100HP. (2) Ρύθμιση της ταχύτητας του PTO στις 540 σ.α.λ. (3) Θρυμματισμός πετρών 1-2 ιντσών σε περάσματα 4 mph. (4) Συλλογή λεπτών σωματιδίων για τη βασική στρώση. (5) Οργώματα μετά τη σύνθλιψη. Δεδομένα: Καθαρίστηκαν 5 στρέμματα/ημέρα. Παραγωγή 40 τόνων χαλικιού. Προκλήσεις: Η υγρή εδαφική λάσπη μείωσε την ταχύτητα κατά 25%, λύθηκε με ξηρότερο χρόνο. Αποτελέσματα: Βελτιωμένη απόδοση φύτευσης κατά 15%, με επαναχρησιμοποιήσιμα αδρανή.

Σταθεροποίηση αυτοκινητοδρόμων στη Βαυαρία (Γερμανία)

Σε δοκιμές του 2023 σε τμήμα μήκους 10 χλμ., ο Σταθεροποιητής Εδάφους χρησιμοποιήθηκε αποτελεσματικά. Διαδικασία: (1) Δείγμα για πλαστικότητα (<20). (2) Ανάμειξη στα 5-7 mph με ελάχιστη ασβέστη. (3) Συμπύκνωση σε στρώσεις. (4) Έτοιμο σε 72 ώρες. Δεδομένα: Καύσιμο 24 λίτρα/ώρα, αντοχή 200 psi. Προκλήσεις: Καθυστέρηση πήξης 10%, αντισταθμιζόμενη από θερμαινόμενο υδραυλικό σύστημα. Αποτελέσματα: 40% λιγότερη εκσκαφή. Η ομάδα σημείωσε συμμόρφωση με τα τοπικά περιβαλλοντικά πρότυπα, καθιστώντας το κατάλληλο για ρυθμιζόμενα έργα υποδομής στην Ευρώπη.

Αποκατάσταση Υπολειμμάτων Σκυροδέματος στη Μίνας Ζεράις (Βραζιλία)

Το 2024, η ομάδα του Watanabe δοκίμασε τον θραυστήρα βράχου σε χώρους αστικών απορριμμάτων σε πλαγιές λόφων, έκτασης 30 στρεμμάτων. Ο ειδικός Carlos Oliveira επέβλεψε τη διαλογή και την επεξεργασία. Διαδικασία: (1) Ταξινόμηση των απορριμμάτων κατά μέγεθος· (2) Σύνθλιψη σε παρτίδες σε ελεγχόμενες τροφοδοσίες· (3) Κόσκινισμα για επαναχρησιμοποιήσιμη πλήρωση· (4) Επιθεώρηση της εξόδου· (5) Επαναχρησιμοποίηση επί τόπου. Δεδομένα: 45 τόνοι/ημέρα, 18 λίτρα/ώρα καυσίμου. Προκλήσεις: Θόρυβος 90 dB που απαιτεί ΜΑΠ και καταστολή σκόνης. Αποτελέσματα: Εξοικονόμηση απόρριψης 35%, οικολογική ανακύκλωση. Αυτή η προσέγγιση ελαχιστοποίησε τη χρήση υγειονομικής ταφής σε ευαίσθητες περιοχές.

Πίνακας Λειτουργικών Διαδικασιών και Προκλήσεων

Αυτός ο πίνακας συνοψίζει τυπικές ροές εργασίας και προβλήματα, με βάση συγκεντρωτικά δεδομένα από παρόμοια μηχανήματα.

| Προϊόν | Διαδικασία Λειτουργίας Βήμα προς Βήμα | Κοινές Προκλήσεις & Μετριασμοί | Βασικές μετρήσεις δεδομένων |

|---|---|---|---|

| Μηχανή σταθεροποίησης εδάφους | 1. Προετοιμασία χώρου και δοκιμή εδάφους· 2. Σύνδεση και βαθμονόμηση· 3. Ανάμειξη με ρυθμιστή υγρασίας· 4. Συμπύκνωση· 5. Σκλήρυνση και επιθεώρηση. | Υγρή τοποθέτηση πλακών (καθυστέρηση 20%): Ρύθμιση υγρασίας· παγώματα: Ζεστάνετε τα υγρά. | Απόδοση: 40-70 τόνοι/ώρα· Καύσιμο: 15-25 L/ώρα· Αύξηση αντοχής: 100-200 psi. |

| Θραυστήρας βράχων | 1. Φόρτωση μέσω εκσκαφέα· 2. Πρωτογενής σύνθλιψη· 3. Δευτερογενής μείωση· 4. Κόσκινο· 5. Έλεγχος συντήρησης. | Φθορά λόγω λειαντικής λειτουργίας (χρόνος εκτός λειτουργίας 10%): Αντικατάσταση εξαρτημάτων· μπλοκαρίσματα: Έλεγχος τροφοδοσίας. | Απόδοση: 45-200 τόνοι/ώρα· Καύσιμο: 18-50 L/ώρα· Διάστημα φθοράς: 1.000-1.200 ώρες. |

| Θραυστήρας πέτρας | 1. Σύνδεση με τρακτέρ· 2. Ρύθμιση ταχύτητας· 3. Σύνθλιψη σε περάσματα· 4. Συλλογή αδρανών υλικών· 5. Οργώμα εάν χρειάζεται. | Βολβός σε βρεγμένο οδόστρωμα (πτώση ταχύτητας 25%): Χρονισμός στεγνού οδοστρώματος· σκόνη: Καταστολή. | Παραγωγή: 30-120 τόνοι/ώρα· Καύσιμο: 16-40 λίτρα/ώρα· Εκκαθάριση: 5-10 στρέμματα/ημέρα. |